Mesh bags are one of the quiet workhorses of commercial laundry programs. Fabric care actually starts before the wash cycle begins, and the bag you choose—whether a lightweight mesh bag or a heavy-duty duffle—determines how well garments hold up, how efficiently loads move through your facility, and how much you spend over time. For procurement teams managing laundry at scale, that choice affects everything from replacement costs to staff workflow.

Mesh bags have earned their place in commercial laundry operations across healthcare, hospitality, and athletic facilities. Duffle-style laundry bags serve a different purpose, often favored for transport and storage. But when does one outperform the other? And which makes sense for bulk orders?

This guide walks through the functional differences, material considerations, and practical applications of both bag types. By the end, you’ll have a clear framework for choosing—and sourcing—the right solution.

What Are Mesh Bags and How Do They Work?

Mesh bags are constructed from woven or knitted fabric with an open, grid-like structure. This design creates thousands of small holes that allow water, detergent, and air to flow freely through the material during washing and drying cycles.

The mesh for bags typically comes in two main weave densities:

- Fine mesh: Small openings (usually 1-2mm) that protect delicate items like lingerie, hosiery, and small accessories from snagging

- Coarse mesh: Larger openings (3-5mm) that allow aggressive water flow for heavily soiled items like athletic uniforms or work clothes

Most mesh laundry bags use polyester as the primary material. Polyester offers strong resistance to repeated washing, maintains shape after hundreds of cycles, and dries quickly. Some manufacturers also produce nylon-based mesh, which provides similar durability with slightly more stretch.

The closure mechanism varies by design. Zippered mesh bags provide secure containment for small items, while drawstring versions allow faster loading and unloading—a factor that matters when processing high volumes.

Why Facilities Choose Mesh Laundry Bags

Commercial operations gravitate toward laundry mesh bags for several practical reasons:

- Contamination control: Items stay separated throughout the wash cycle, preventing cross-contamination between departments or residents

- Inventory protection: Delicate items wash safely without direct agitation against machine drums

- Processing efficiency: Pre-sorted loads move faster through wash, dry, and fold stages

- Cost reduction: Garments last longer when protected, reducing replacement frequency

Healthcare facilities particularly value mesh bags for infection control protocols. Soiled linens go directly into the bag at the point of use, travel to laundry without handling, and wash inside the bag—minimizing staff exposure.

What Are Laundry Duffle Bags and Where Do They Excel?

Laundry duffle bags take their design cues from traditional travel duffles. They feature solid fabric construction—typically canvas, nylon, or polyester—with cylindrical or rectangular shapes and carrying handles or shoulder straps.

Unlike mesh construction, duffle bag laundry solutions provide complete coverage. No openings means no visibility into contents, which can be either an advantage or limitation depending on your application.

Common Duffle Bag Materials

| Material | Durability | Water Resistance | Weight | Best For |

|---|---|---|---|---|

| Canvas | High | Low (untreated) | Heavy | Heavy-duty transport |

| Nylon | High | Moderate | Light | Travel, portable use |

| Polyester | Moderate | Low | Light | Budget applications |

| Coated fabric | High | High | Moderate | Outdoor, wet environments |

Duffle bags shine in transport scenarios. College students hauling laundry to shared facilities, travelers packing dirty clothes separately from clean items, and facilities collecting laundry from multiple rooms all benefit from the duffle format.

The solid construction also provides privacy. Gym members, hotel guests, and residential care patients may prefer that their personal items remain hidden during transport.

Limitations for Commercial Washing

Here’s where duffle bags show their constraints. Solid fabric doesn’t allow water to penetrate evenly during wash cycles. Items stuffed inside a closed duffle won’t get clean—the bag must be emptied before washing.

This creates extra handling steps:

- Transport items in duffle

- Empty contents into machine or mesh bag

- Wash items

- Reload duffle for return transport

For high-volume operations, these extra steps multiply across hundreds or thousands of loads daily. The labor cost often outweighs any savings on bag price.

Mesh Bags vs Duffle Bags: Direct Comparison

Understanding when to choose mesh bags over duffle bags—and vice versa—comes down to matching features with your specific operational needs.

Airflow and Wash Performance

Mesh bags: Water and detergent flow directly through the fabric, reaching all items inside. Garments agitate freely within the bag’s confines, ensuring thorough cleaning. Drying happens efficiently because air circulates through the mesh.

Duffle bags: Must be emptied before washing. The solid construction that protects items during transport becomes a barrier in the machine. Items washed inside a closed duffle emerge still dirty—or worse, develop mold from trapped moisture.

Winner for washing: Mesh bags, decisively.

Protection During Transport

Mesh bags: The open weave means contents are visible. Items can potentially catch on external surfaces if mesh openings are large enough. Less structural rigidity means the bag conforms to its contents rather than maintaining shape.

Duffle bags: Solid walls protect contents from snags, dirt, and prying eyes. Rigid construction keeps the bag upright and organized. Handles and straps make carrying comfortable over distances.

Winner for transport: Duffle bags, for privacy and protection.

Durability Over Time

Both bag types can last for years with proper material selection. However, the wear patterns differ:

| Factor | Mesh Bags | Duffle Bags |

|---|---|---|

| Wash cycle stress | Designed for repeated washing | Not designed for machine washing |

| Seam strength | Moderate (stress distributed across mesh) | High (solid fabric holds seams well) |

| Zipper longevity | Moderate | High |

| Fabric breakdown | Gradual mesh stretching | Fabric wear, fading |

| Typical lifespan | 200-500+ wash cycles | 2-5 years of transport use |

Cost Considerations for Bulk Orders

When ordering mesh bags bulk quantities, unit costs drop significantly. A manufacturer producing thousands of units can offer per-piece pricing that makes mesh bags extremely economical for commercial use.

Duffle bags typically cost more per unit due to:

- More fabric per bag

- Additional hardware (zippers, handles, straps)

- More complex construction

For facilities processing laundry on-site, the lower per-unit cost of mesh laundry sack options—combined with their wash-ready design—usually delivers better value over time.

Choosing Mesh Bags: When They’re the Right Call

Mesh bags earn their keep in scenarios where wash performance and processing efficiency take priority. Here’s where they deliver the most value.

Healthcare and Senior Care Facilities

Infection control protocols often require that soiled items remain contained from point of use through the entire wash cycle. Mesh bags make this possible. Staff place soiled linens directly into the bag at bedside, the sealed bag travels to laundry, and washing happens without anyone handling contaminated items directly.

Water-soluble mesh bags take this further—the bag itself dissolves during washing, eliminating the need to open it at all. Standard polyester mesh bags work for general use where dissolution isn’t required.

A set of fine mesh bags works well for delicate resident garments, while coarse mesh options handle heavier items like towels and bed linens.

Hotels and Hospitality

Guest laundry services benefit from mesh bags in multiple ways:

- Delicates stay protected during wash

- Items remain sorted by guest or room

- Quick visual identification of contents

- Fast drying reduces turnaround time

Housekeeping departments also use large mesh laundry bags to collect soiled linens floor by floor, keeping counts organized and preventing mix-ups.

Athletic Programs and Fitness Centers

Sweaty uniforms and gym towels need aggressive washing—but not at the expense of fabric damage. Mesh bags allow full water penetration while preventing items from tangling with each other or wrapping around agitators.

Team managers often assign numbered mesh bags to individual athletes, simplifying distribution after washing. The visible contents also make inventory checks quick.

Garment Manufacturing and Retail

Quality control teams use mesh bags to protect sample garments during test washes. Production facilities process fabric swatches and prototype items in mesh to evaluate colorfastness and shrinkage without risking damage from direct machine contact.

Retail operations washing customer returns or display items also prefer mesh—it protects garments while allowing thorough cleaning.

Choosing Duffle Bags: Where They Make Sense

Duffle bags aren’t washing bags—they’re transport and storage solutions. Recognizing this distinction helps identify their proper applications.

Residential and Shared Laundry Situations

Apartment dwellers, dormitory residents, and anyone using shared laundry facilities need a way to carry clothes to and from machines. Duffle bags serve this purpose well. The solid sides keep items contained, handles make carrying easy, and the bag protects clean clothes on the return trip.

The catch: items still need to come out of the duffle before washing. For personal use, this extra step is manageable. For commercial operations handling hundreds of loads, it’s a bottleneck.

Travel and Temporary Storage

Duffle bags excel at separating dirty laundry from clean clothes during trips. The solid construction prevents odors from spreading to other items in luggage. Upon returning home, the entire duffle goes to the laundry area for emptying and washing.

Collection Points and Sorting Areas

Facilities that collect laundry from multiple sources sometimes use duffle bags at the collection stage, then transfer contents to mesh bags for actual washing. This two-bag system makes sense when:

- Privacy during collection matters

- Items travel long distances before processing

- Sorting happens at a central location

The additional handling adds labor, so this approach only makes sense where the benefits—usually privacy or protection during transport—justify the extra steps.

Material Selection: What to Look for in Mesh Bags

Not all mesh is equal. The material and construction quality determine how long your bags last and how well they perform across hundreds of wash cycles.

Polyester vs. Nylon Mesh

Polyester mesh dominates commercial applications for good reasons:

- Excellent resistance to repeated washing

- Maintains shape and doesn’t stretch significantly

- Dries quickly

- Lower cost than nylon

- Wide availability in various weave densities

Nylon mesh offers advantages in specific situations:

- Slightly stronger tensile strength

- More abrasion resistant

- Better suited for very heavy loads

- More expensive

For most bulk purchasing decisions, polyester mesh delivers the best balance of performance and value.

Weave Density Considerations

The size of mesh openings affects both protection and water flow:

| Mesh Type | Opening Size | Best For | Considerations |

|---|---|---|---|

| Ultra-fine | <1mm | Hosiery, jewelry, very small items | Slower water penetration |

| Fine | 1-2mm | Lingerie, delicates, dress shirts | Good protection, good flow |

| Medium | 2-3mm | General garments, uniforms | Balanced performance |

| Coarse | 3-5mm | Towels, bedding, heavy items | Maximum water flow |

Facilities often stock multiple mesh densities to match different item types. A thickened fine mesh set handles delicates, while coarse mesh bags process bulkier loads.

Construction Quality Indicators

When evaluating mesh bags for bulk orders, examine these features:

Seam construction: Double-stitched seams resist the pulling forces during wash and spin cycles. Single-stitch construction fails faster.

Zipper quality: If the bag uses a zipper closure, the zipper should move smoothly and feature a protective flap to prevent snagging. Plastic zippers generally outlast metal in laundry applications—they don’t corrode and run smoother when wet.

Drawstring durability: For drawstring closure bags, look for reinforced grommets and thick, woven cord that won’t fray after repeated tightening.

Corner reinforcement: High-stress points at corners should have additional stitching or fabric layers.

Sizing and Capacity Planning for Commercial Use

Ordering the right sizes in appropriate quantities prevents both shortages and wasted storage space. Here’s how to approach capacity planning for mesh bags bulk orders.

Standard Size Categories

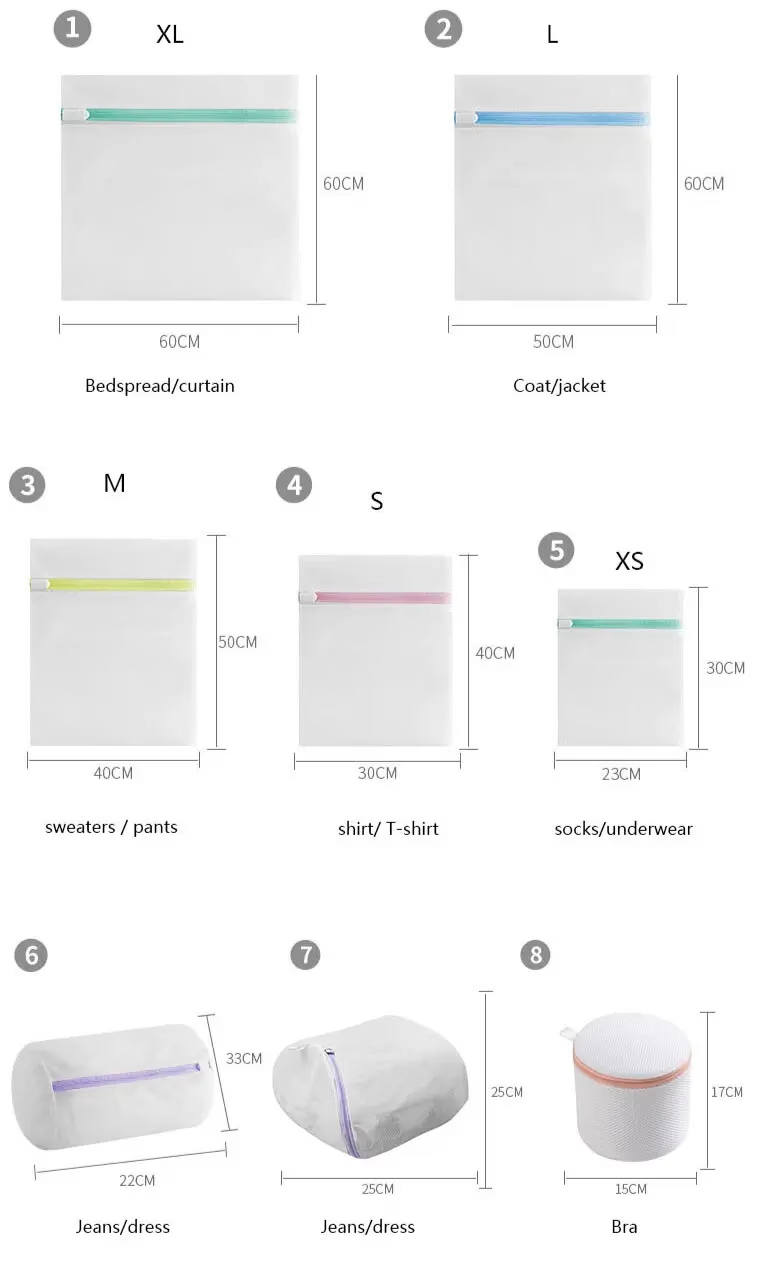

| Size | Approximate Dimensions | Typical Capacity | Common Uses |

|---|---|---|---|

| Small | 30 x 40 cm | 1-3 items | Delicates, undergarments |

| Medium | 40 x 50 cm | 3-6 items | Shirts, pants, small loads |

| Large | 50 x 70 cm | 6-10 items | Full outfit, uniforms |

| Extra Large | 60 x 90 cm | 10-15+ items | Bedding, bulk items |

| Oversized | 70 x 100+ cm | 15-25+ items | Linens, institutional loads |

Most facilities need a mix. A typical order ratio might look like:

- 20% small bags for delicates

- 30% medium bags for general garments

- 35% large bags for standard loads

- 15% extra large/oversized for linens

Volume Estimation

Calculate your mesh bag needs based on:

- Daily load volume: How many individual loads does your facility process?

- Cycle time: How long do bags stay in circulation before returning to stock?

- Replacement rate: How often do bags need replacing due to wear?

- Buffer stock: What percentage extra do you need for peak periods?

Example calculation:

- A hotel processes 200 guest laundry loads daily

- Average cycle time: 2 days (pickup to return)

- That’s 400 bags in active circulation

- Add 25% buffer for peaks and repairs: 500 bags needed

- At a 12-month replacement cycle: reorder 500 bags annually

Customization Options

Direct manufacturers offer customization that distributors typically cannot match:

- Color coding: Different colors for different departments, floors, or item categories

- Size variations: Custom dimensions for specific equipment or items

- Logo printing: Facility branding for identification and theft deterrence

- Closure modifications: Specific zipper lengths, drawstring materials, or locking mechanisms

When you work directly with a manufacturer, these customizations often add minimal cost—especially on larger orders.

Compliance and Safety Considerations

Commercial laundry operations must meet regulatory standards. The bags you use play a role in maintaining compliance.

REACH Compliance for European Markets

The REACH regulation (Registration, Evaluation, Authorisation and Restriction of Chemicals) governs chemical safety for products sold in the European Union. Mesh bags destined for EU markets must demonstrate that their materials don’t contain restricted substances above permitted thresholds.

Reputable manufacturers test their materials and can provide REACH compliance documentation. This matters particularly for:

- Healthcare facilities under strict material regulations

- Hotels serving international guests

- Any facility exporting laundered goods to Europe

When evaluating suppliers, request REACH test certificates. Manufacturers who cannot provide this documentation may be using materials that fail compliance standards.

Flammability Standards

Some applications require flame-retardant materials. Industrial laundries processing workwear for oil and gas, manufacturing, or fire service operations may need bags that meet specific flammability ratings.

Standard polyester mesh doesn’t typically carry flame-retardant properties unless specifically treated. If your operation requires this, specify the need during the ordering process.

Healthcare-Specific Requirements

Medical facilities often work under guidelines from organizations like the Association for the Healthcare Environment (AHE) that specify laundry handling procedures. Mesh bags used in healthcare settings should support:

- Hands-free loading to minimize contamination

- Secure closure to prevent spillage during transport

- Material that withstands high-temperature washing

- Color-coding options for contamination level identification

Working with a Direct Manufacturer vs. Distributors

The sourcing channel you choose affects pricing, customization options, and support quality. Understanding the differences helps you make informed purchasing decisions.

Direct Manufacturer Advantages

Ordering mesh laundry bags directly from a manufacturer provides several benefits:

Lower per-unit costs: Without distributor markups, the price per bag drops—often significantly on bulk orders. The savings compound across large orders and repeat purchases.

Customization flexibility: Manufacturers control their production lines. Adjusting sizes, colors, mesh density, closure types, or adding logo printing happens at the source. Distributors can only offer what’s already in their inventory or relay custom requests back to manufacturers (adding time and cost).

Technical expertise: Production teams understand material properties, construction methods, and durability factors at a detailed level. Questions about specific applications get informed answers, not sales-driven guesses.

Quality control: Direct relationships mean direct accountability. If quality issues arise, you’re working with the people who made the product—not intermediaries who purchased it themselves.

Minimum order flexibility: Established manufacturers often accommodate smaller initial orders to build relationships, then scale with your needs. They can also handle very large orders that would strain distributor inventories.

When Distributors Make Sense

Distributors serve a purpose in certain scenarios:

- Very small orders where manufacturer minimums exceed needs

- Need for diverse product categories from a single vendor

- Local inventory for immediate availability

- Situations where total spend doesn’t justify direct sourcing relationships

For most commercial operations ordering mesh bags bulk quantities, direct manufacturer relationships deliver better value.

Evaluating Potential Suppliers

Whether working with manufacturers or distributors, assess suppliers on:

| Factor | Questions to Ask |

|---|---|

| Experience | How long have they manufactured/sold mesh bags? |

| Capacity | Can they handle your volume requirements? |

| Compliance | Can they provide REACH and other certifications? |

| Customization | What modifications do they offer? |

| Lead times | How quickly can they fulfill orders? |

| Samples | Will they provide samples before bulk orders? |

| Communication | Do they respond promptly and clearly? |

| References | Can they provide client references in your industry? |

Our company, established in 2014, manufactures laundry mesh bags, bra laundry bags, washing bags for shoes, storage bags, laundry baskets, and drawstring mesh products. Customers span Europe, North America, South America, Korea, and Japan. OEM orders are welcome, customized designs are available, and all raw materials are environment-friendly with products passing REACH and related testing. You can explore our full product range to see available options.

Hybrid Solutions: Using Both Bag Types Together

Some operations benefit from combining mesh bags and duffle bags at different stages of their laundry workflow.

The Two-Bag System

In facilities where items travel significant distances before reaching laundry equipment, a hybrid approach works like this:

- Collection stage: Items go into duffle bags at point of origin (guest rooms, patient rooms, locker rooms)

- Transport stage: Duffle bags travel to the central laundry facility

- Processing stage: Contents transfer from duffles into mesh bags sorted by type, temperature requirement, or destination

- Washing stage: Mesh bags go through wash and dry cycles

- Return stage: Clean items return in fresh duffle bags or directly to storage

This approach combines the transport advantages of duffle bags with the wash performance of mesh bags. The trade-off is additional handling labor at the transfer point.

When Hybrid Makes Sense

Consider a two-bag system when:

- Collection points are far from processing facilities

- Privacy during collection matters to clients or residents

- You need rigid containers for transport but mesh for washing

- Different departments prefer different collection methods

Simplifying Where Possible

For many operations, mesh bags handle the entire workflow efficiently. Items go directly into mesh at point of origin and stay there through washing—eliminating transfer steps entirely.

The choice depends on your specific constraints, labor costs, and operational priorities. Testing both approaches with actual workflow data often reveals which delivers better efficiency for your situation.

A colorful mesh bag set can enable visual sorting at collection points, making later processing faster. Alternatively, patterned mesh bags work well in residential or hospitality settings where aesthetic presentation matters.

Making Your Decision: A Practical Framework

With all factors considered, here’s a framework for deciding between mesh bags and duffle bags—or determining the right mix.

Choose Mesh Bags When:

- Items will be washed inside the bag

- Processing speed and efficiency matter

- You need contamination control (healthcare, food service)

- Bulk pricing and low per-unit cost are priorities

- Garment protection during washing is needed

- Quick drying reduces turnaround time

- Visual identification of contents helps workflow

Choose Duffle Bags When:

- Primary need is transport, not washing

- Privacy of contents matters

- Items will be emptied before machine washing

- You need rigid containers that hold their shape

- Carrying comfort over distances is important

- Storage organization is the main goal

Questions to Ask Your Team

Before placing orders, gather input on:

- What’s our current bag replacement frequency?

- Where in our workflow do bags fail or cause problems?

- How much handling time does our current system require?

- What compliance or certification requirements must we meet?

- What customization would improve our operations?

- What’s our realistic budget per unit?

- How important is working with a direct manufacturer?

The answers guide not just which bag type to choose, but also specific features, quantities, and supplier relationships.

Ready to Source the Right Solution?

Whether you need mesh bags for commercial washing operations, duffle bags for transport, or a combination of both, the key is matching product capabilities to your actual workflow requirements.

For facilities processing laundry on-site, mesh laundry bags typically deliver better efficiency, lower long-term costs, and superior wash results. The ability to wash items inside the bag—without extra handling steps—saves labor and time across every load.

As a direct manufacturer with over a decade of experience producing laundry mesh bags for clients across Europe, North America, South America, Korea, and Japan, we offer advantages that distributors simply cannot match: competitive bulk pricing, flexible customization options, REACH-compliant materials, and direct communication with production teams who understand your needs.

OEM orders are welcome. Custom sizes, colors, logo printing, and closure modifications are all available. Our environment-friendly raw materials pass REACH and related testing, meeting the standards required for healthcare, hospitality, and institutional applications.

Request samples to evaluate quality firsthand. Reach out with your specifications for a detailed quote. Working directly with the manufacturer means getting exactly what your operation needs—without middleman markups or communication delays.

Contact us to discuss your requirements and request samples →

Frequently Asked Questions

1. What is the minimum order quantity for mesh bags bulk purchases?

Minimum order quantities vary depending on product specifications and customization requirements. Standard products typically have lower minimums than fully custom designs. Contact us directly with your specifications—we work with clients to find solutions that fit their volume needs, whether that’s an initial trial order or ongoing bulk supply.

2. Can mesh laundry bags be customized with company logos?

Yes, logo printing and custom branding are available. Options include single-color printing, multi-color designs, and placement on various positions of the bag. Minimum quantities apply for custom printing runs. Reach out with your artwork and quantity estimates for specific pricing and lead times.

3. How long do mesh bags typically last in commercial laundry settings?

Quality mesh bags constructed from durable polyester typically withstand 200-500+ wash cycles under normal commercial conditions. Factors affecting lifespan include wash temperature, chemical exposure, load weight, and mechanical stress. Our products use reinforced seams and quality materials designed for extended commercial use.

4. Do your products meet REACH compliance for European markets?

Yes. Our raw materials are environment-friendly and our products pass REACH and related testing required for sale in European Union markets. We can provide compliance documentation upon request for procurement teams requiring certification records.

5. How quickly can orders be fulfilled and shipped internationally?

Lead times depend on order complexity, quantity, and customization requirements. Standard products ship faster than custom designs requiring production setup. We serve clients across Europe, North America, South America, Korea, and Japan regularly. Contact us with your timeline requirements for accurate delivery estimates to your region.