That favorite pair of sneakers. You wear them everywhere—from morning commutes to weekend adventures. But now they carry the evidence of every step, looking dull and smelling less than fresh. Tossing them directly into the washing machine feels like a risky gamble. You can almost hear the loud, rhythmic thudding against the drum and picture the scuffs and damage that follow. It’s a common problem: you want clean shoes, but you don’t want to destroy them or your expensive appliance in the process. There is a simple, effective solution that protects your investment. High-quality washing bags for shoes provide a cushioned barrier, allowing for a deep clean while preventing the very damage you fear.

What Exactly Are Washing Bags for Shoes?

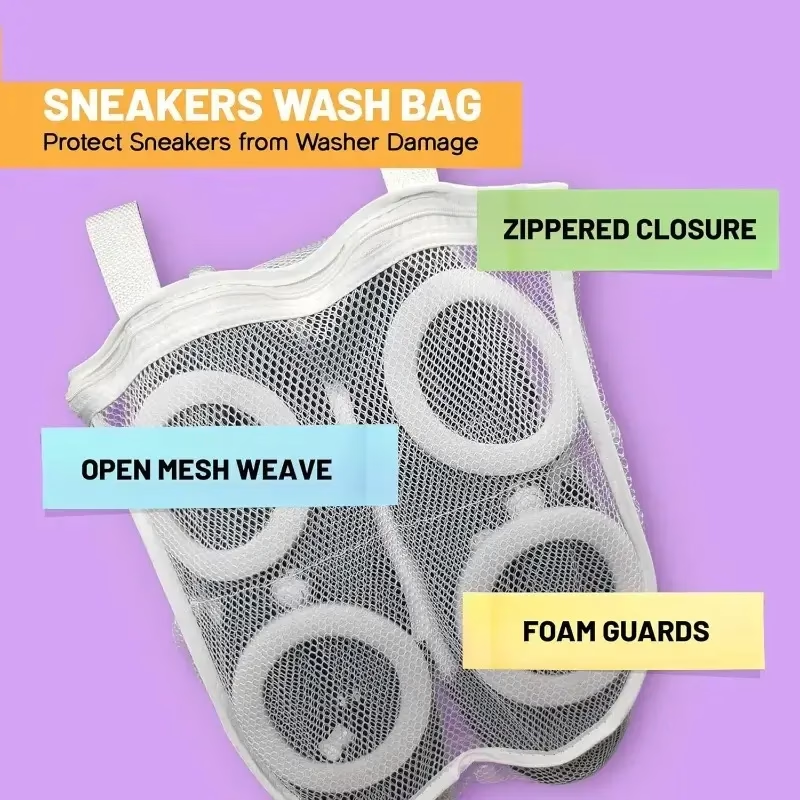

At its core, a shoe washing bag is a protective container designed specifically for laundering footwear in an automatic washing machine. Think of it as a piece of safety equipment for your sneakers. But not all bags are created equal. A well-designed bag is much more than just a simple pouch.

They are typically crafted from a durable, porous mesh material, most often polyester. This material is chosen for its strength and resistance to stretching, shrinking, and chemicals found in detergents. The mesh construction is critical; it allows water and soap to flow through freely, cleaning the shoes thoroughly from every angle. At the same time, it prevents abrasive elements like shoelace eyelets or buckles from snagging on other items or scratching the inside of your washing machine drum.

The construction of these bags features several key elements. A robust, rust-proof zipper is essential for keeping the shoes securely inside throughout the entire wash cycle. The best designs include an elastic “zipper garage” or cover. This clever feature prevents the metal zipper pull from clanking against the machine’s interior or snagging on other laundry items. Many premium bags also incorporate layers of foam padding or a structured honeycomb design, creating a cushioned cage that absorbs impact and helps the shoes maintain their shape.

The Risks of Machine Washing Shoes Without Protection

Tossing a pair of running shoes into the wash unprotected might seem like a quick fix, but the potential consequences can be costly. Both your footwear and your washing machine are at risk of significant damage.

For your shoes, the violent tumbling action of a wash cycle is the primary enemy. Without a protective barrier, they are free to slam against the hard metal drum hundreds of times. This can lead to a host of problems:

Scuffing and Abrasion: The outer material, whether it’s leather, canvas, or synthetic fabric, can get scuffed, scratched, and worn down.

Deformation: The force of the spin cycle can crush the toe box and heel counter, causing the shoes to lose their original shape and supportive structure.

Adhesive Failure: The heat and excessive water exposure can weaken the glue that holds the sole to the upper part of the shoe, leading to separation.

Damaged Laces and Eyelets: Laces can get tangled, stretched, or frayed. Metal eyelets can chip or get bent out of shape.

Your washing machine is also in jeopardy. The sound of heavy sneakers banging around isn’t just annoying; it’s a sign of potential harm.

Drum Damage: Shoes, especially those with hard soles or metal components, can scratch, dent, or even crack the inner drum of the washer.

Imbalance and Wear: A heavy, waterlogged pair of shoes can easily unbalance the drum during the spin cycle. This causes violent vibrations that put immense strain on the machine’s suspension, motor, and bearings, leading to premature wear and expensive repairs. According to experts, unbalanced loads are a leading cause of washing machine malfunctions.

Clogs and Blockages: Small stones or debris lodged in the shoe treads can dislodge during the wash and get stuck in the machine’s filter or drain pump, causing clogs.

Using a dedicated bag mitigates all these risks, turning a hazardous activity into a safe and routine part of shoe care.

The Core Benefits of Using a Sneaker Washing Bag

A sneaker washing bag is a small investment that delivers significant returns in preservation, protection, and cleanliness. By simply placing your shoes inside before washing, you unlock a range of benefits that make the entire process safer and more effective.

Preserving Shoe Integrity

The primary function of the bag is to act as a cushion. The mesh and any integrated padding absorb the shock of the tumbling motion. This prevents the shoes from directly striking the washer drum, dramatically reducing the risk of scuffs, dents, and fabric abrasion. The bag keeps the pair of shoes contained together, which also stops them from twisting into unnatural positions that could compromise their structure and fit. Glued components, like the outsole, are shielded from the most intense forces, extending the shoe’s lifespan.

Protecting Your Washing Machine

As mentioned, unprotected shoes can wreak havoc on an appliance. A shoe washing bag effectively neutralizes this threat. By containing the footwear, the bag prevents heavy soles and sharp-edged eyelets from scratching or denting the drum. It also helps to keep the load more balanced, especially when you add a few towels alongside it. This reduces the violent shaking and vibrations that strain the machine’s internal components, saving you from potential repair bills and ensuring your appliance runs smoothly for years to come.

Ensuring a Deeper, Safer Clean

You might wonder if washing shoes inside a bag compromises the cleaning process. The opposite is actually true. A quality sneaker washing bag is engineered for maximum water and detergent flow. The porous mesh allows the cleaning solution to penetrate every part of the shoe, from the upper to the inner lining. Furthermore, the bag acts as a filter. It allows dirt and grime to be washed away from the shoe but can prevent larger debris, like pebbles stuck in the tread, from entering and clogging the washing machine’s drain system. This results in a cleaner shoe and a healthier machine.

Versatility Beyond Sneakers

While designed for footwear, these bags are incredibly versatile. Their protective qualities make them perfect for washing other delicate or cumbersome items. You can use them for:

Slippers and house shoes

Small stuffed animals

Hats and baseball caps (check care labels first)

Lingerie and other delicates that need extra protection

Baby shoes and socks

This multi-purpose functionality makes it a valuable addition to any laundry room.

Choosing the Right Washing Bags for Your Product Line

For businesses looking to source these products, understanding the nuances of construction and material is key to offering a valuable item to your customers. Not all washing bags for shoes are made with the same attention to detail. Distinguishing between a low-cost, disposable item and a durable, premium product comes down to a few critical factors.

Material Matters: Polyester Mesh Grades and Durability

The heart of the bag is its mesh. The quality of this material will determine the bag’s performance and longevity.

Mesh Density: Look for a fine, yet strong, mesh. A mesh that is too open may allow shoelace hooks to snag, while one that is too dense can impede water flow. A high-density polyester is ideal, offering a balance of permeability and protection.

Layering: Premium bags often feature a multi-layer construction. This might include an inner and outer layer of mesh with a thin, resilient foam layer sandwiched in between. This “triple-layer” design provides superior cushioning and structural support compared to a single, flimsy layer.

Material Compliance: For markets in Europe and beyond, raw materials must be environmentally friendly and safe. Ensure your supplier can provide proof of compliance with standards like the REACH test, which screens for substances of very high concern. This is a powerful selling point for conscientious consumers.

Construction and Design Features to Look For

The small details in design separate a mediocre bag from a great one.

Zippers: The zipper is the most common point of failure. Insist on rust-proof zippers made from high-quality nylon or coated metal. The most critical feature is an “auto-lock” function. This prevents the zipper from sliding open during the vigorous wash cycle. A protective elastic or fabric hood—the “zipper garage”—is also a must-have to prevent noise and snagging.

Padding and Structure: The shape of the bag matters. Cylindrical bags are often better for bulkier footwear like basketball sneakers, as they provide 360-degree protection. Rectangular bags are great for standard shoes. The best bags have built-in padding, either from foam inserts or a 3D honeycomb-like fabric structure. This padding is light, allows water to pass through, and provides exceptional impact resistance.

Sizing and Seams: Offer a variety of sizes to accommodate different types of footwear, from children’s shoes to adult high-tops. Inspect the seams carefully. They should be double-stitched or have reinforced serged edges to withstand repeated stress without tearing.

Comparison Table: Standard vs. Premium Shoe Bag Features

| Feature | Standard Bag | Premium Bag |

| Material | Single-layer, low-density polyester mesh. | High-density, triple-layer mesh with foam core. |

| Zipper | Basic plastic or metal zipper, no lock. | Rust-proof auto-locking zipper with protective cover. |

| Padding | None or minimal. | Integrated foam or 3D honeycomb padding. |

| Structure | Simple flat pouch. | Structured cylindrical or rectangular shape. |

| Best For | Lightweight canvas shoes, infrequent use. | Heavy sneakers, boots, frequent use. |

| Lifespan | May last only a few washes. | Designed to last for hundreds of washes. |

A Step-by-Step Guide to Using Washing Bags for Shoes

To get the best results and ensure the longevity of both the shoes and the bag, following a simple process is key. It’s not just about tossing the bag in the machine; proper preparation and drying are just as important. For a deeper dive into cleaning various shoe types, guides like this one from Good Housekeeping offer excellent tips.

Step 1: Preparation is Key

Before the shoes go anywhere near the water, a few minutes of prep work will make a world of difference.

Remove Loose Dirt: Take the shoes outside and clap the soles together to dislodge any caked-on mud, rocks, or grass. Use a soft brush to wipe away any remaining surface dirt and debris from the uppers and soles. This prevents excess grime from turning into a muddy mess inside your washer.

Remove Laces and Insoles: If possible, remove the laces and insoles from the shoes. These can be washed in the same bag, but separating them allows water and detergent to better reach all the nooks and crannies. Washing laces separately also prevents them from getting tangled.

Pre-Treat Stains: For stubborn stains like oil or grass, apply a small amount of stain remover or a paste of laundry detergent and water directly to the spot. Let it sit for about 15-20 minutes before washing.

Step 2: The Washing Process

Now it’s time for the main event.

Bag the Shoes: Place one pair of shoes into a single washing bag for shoes. It’s best not to overcrowd the bag. If washing laces and insoles, you can place them inside as well. Securely close the zipper and make sure the pull is tucked into its protective elastic cover.

Balance the Load: This is a crucial step. Never wash shoes by themselves. A single, heavy bag will throw the machine off balance. Add a few old towels or sturdy rags to the drum along with the bagged shoes. This not only balances the load but also provides additional cushioning and helps scrub the shoes clean.

Select the Right Settings: Use a small amount of liquid laundry detergent; powder detergents can sometimes get trapped in the fabric if they don’t dissolve fully. Choose the delicate or gentle cycle on your washing machine. Most importantly, always use cold water. Hot water can damage synthetic materials and weaken the adhesives in many athletic shoes.

Step 3: The Drying Process

Never, ever put sneakers in a clothes dryer. The high heat will warp the plastic and rubber components, melt the glue, and cause the entire shoe to shrink and deform, ruining its fit and support. Air drying is the only safe method.

Remove and Reshape: As soon as the wash cycle is finished, remove the shoe bag from the machine. Take the shoes, laces, and insoles out of the bag.

Stuff the Shoes: To help the shoes maintain their shape as they dry and to speed up the process, stuff them with absorbent material. White paper towels, newspaper, or even small, dry washcloths work perfectly. Avoid colored paper as the ink can bleed onto the shoe’s interior.

Find a Good Spot: Place the shoes, insoles, and laces in a well-ventilated area away from direct sunlight or heat sources. Direct sun can cause fading and make materials brittle. Let them air dry completely, which may take anywhere from 8 to 24 hours depending on the humidity.

Manufacturing Insights: What Sets Professional-Grade Sneaker Washing Bags Apart

For procurement managers, brand developers, and wholesalers, understanding the production process is vital for sourcing a product that reflects your company’s standards for quality. The difference between a bag that falls apart after two uses and one that becomes a laundry staple lies in the materials, quality control, and manufacturing expertise.

Sourcing Environmentally-Friendly Raw Materials

Today’s market is driven by more than just price. Consumers are increasingly aware of the environmental impact of their purchases. Sourcing from a manufacturer that prioritizes eco-friendly materials is not just responsible, it’s a competitive advantage.

Compliance is Non-Negotiable: For products destined for European, North American, or Japanese markets, compliance with regulations like REACH is essential. This certifies that the raw materials—the polyester mesh, the foam, the zipper—are free from harmful chemicals. A manufacturer should be able to provide documentation and testing reports to verify these claims.

Sustainable Polyester: Look for partners who can source or utilize recycled polyester (rPET) in their production. This demonstrates a commitment to sustainability that can be a powerful story for your brand.

The Importance of Quality Control in Production

A superior product is the result of rigorous quality control at every stage of manufacturing.

Stitching Strength: The seams are the skeleton of the bag. A reliable manufacturer uses reinforced stitching techniques, like double-stitching or overlocking, to ensure seams can withstand the pulling and stretching of heavy, waterlogged shoes in a spin cycle. Random samples should be pull-tested to verify seam strength.

Zipper Integrity: Zippers should be tested for durability and functionality. This includes cycle testing (opening and closing hundreds of times) and ensuring the auto-lock mechanism functions correctly under stress.

Final Inspection: Every single bag should undergo a final manual inspection to check for cosmetic flaws, correct zipper placement, and overall structural integrity before it is packaged.

Customization and OEM Opportunities

A true manufacturing partner works with you to create a product that aligns with your brand. Standard, off-the-shelf bags are a starting point, but customization offers the greatest value. As an original equipment manufacturer (OEM), we provide extensive options:

Branding: Add your logo via a woven label, a printed tag, or a custom zipper pull.

Sizing and Shape: We can develop custom dimensions and shapes to fit specific types of footwear, from golf shoes to heavy-duty work boots.

Colors and Materials: Choose from a wide palette of colors for the mesh, trim, and zipper to match your brand’s aesthetic.

Packaging: Develop custom retail packaging, from simple poly bags with printed inserts to fully branded cardboard boxes.

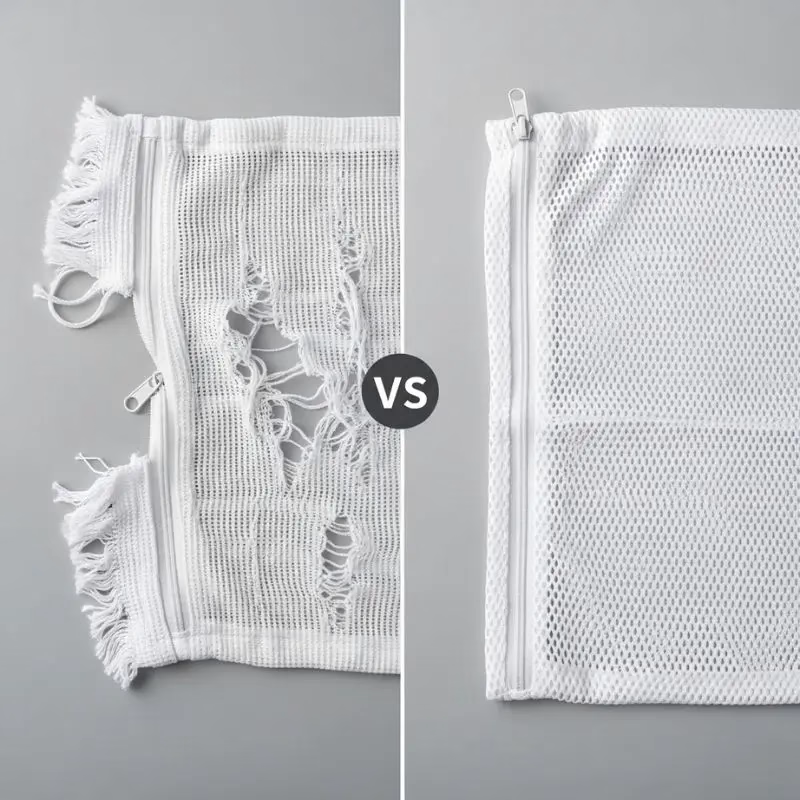

Comparison Table: Low-Quality vs. Professional-Grade Manufacturing

| Characteristic | Low-Quality Import | Professional-Grade Bag |

| Seams | Single-stitched with weak thread; prone to tearing. | Reinforced, double-stitched with high-tensile thread. |

| Zipper | Cheap metal that rusts or plastic that breaks; no lock. | Rust-proof, auto-locking zipper with a protective cover. |

| Mesh | Thin, single-layer mesh that easily tears or snags. | Durable, multi-layer, high-density mesh optimized for flow. |

| Lifespan | May survive only 1-5 wash cycles before failing. | Rigorously tested to withstand 100+ wash cycles. |

| Compliance | Often undocumented materials; may fail safety/eco tests. | Fully documented, REACH-compliant, eco-friendly materials. |

A Smarter Way to Clean Your Shoes

Your footwear is an important part of your daily life, and keeping it clean shouldn’t be a chore that risks damage. Washing bags for shoes offer a straightforward, affordable, and highly effective way to protect both your shoes and your washing machine. They transform a potentially destructive process into a safe, routine part of maintenance.

By choosing a bag built with high-quality, durable, and eco-friendly materials, you ensure a better clean and a longer life for your favorite sneakers. For businesses, sourcing a well-manufactured product with thoughtful design features provides real value to your customers and enhances your brand’s reputation for quality.

Become a Leader in High-Quality Laundry Solutions

Since 2014, we have been the original manufacturer behind some of the world’s most trusted laundry care products. With deep experience in creating durable, eco-friendly mesh laundry bags, washing bags for shoes, and storage solutions for global markets, we understand what quality means. We handle everything from raw material sourcing to final inspection, offering extensive OEM and custom design opportunities.

Partner with a manufacturer that prioritizes quality, compliance, and your brand’s success.

Contact our team today to discuss your project, request a sample, or receive a quote for your next bulk order.

FAQs

What are your typical minimum order quantities (MOQs) for custom-branded sneaker washing bags? Our MOQs are flexible and designed to accommodate businesses of various sizes. For standard models with logo customization, MOQs typically start at 1,000 units. For fully custom designs involving unique sizing or materials, the MOQ may be higher. We encourage you to contact our sales team to discuss the specific needs of your project.

Can your washing bags for shoes be engineered to fit specialty footwear, such as steel-toed work boots or oversized boots? Absolutely. As an OEM manufacturer, one of our core strengths is custom design. We can engineer bags with specific dimensions, reinforced materials, and heavy-duty construction suitable for larger and heavier footwear like work boots, hiking boots, or specialty athletic cleats. We can develop prototypes to ensure the final product meets your exact specifications.

What material and product compliance certifications, such as REACH, can you provide for your products? We are committed to safety and environmental responsibility. Our standard raw materials are sourced to be compliant with major international standards, including Europe’s REACH regulations and California’s Proposition 65. We can provide all necessary documentation and third-party testing reports for our materials upon request to ensure your products meet the requirements of your target market.

What is the standard production lead time for a bulk OEM order of shoe washing bags? The typical lead time for a bulk order is between 30 and 45 days after the final sample approval and deposit. This timeframe can vary depending on the complexity of the customization, order volume, and current production schedules. We always provide a detailed timeline upfront and maintain clear communication throughout the product