Your mesh laundry sack just ripped. Again. Those delicate silk blouses and cashmere sweaters you were protecting? Now they’re tangled with rougher fabrics, potentially snagged or stretched. The frustration builds when you realize you’ve been buying replacement bags every few months, wasting money and creating unnecessary waste. Here’s the thing—not all mesh laundry sacks perform equally. The material makes all the difference between a bag that lasts years and one that falls apart after a dozen washes. Understanding whether nylon or polyester serves your needs better can save you from constant replacements and protect your valuable garments for the long haul.

Understanding Mesh Laundry Sack Materials: The Foundation of Durability

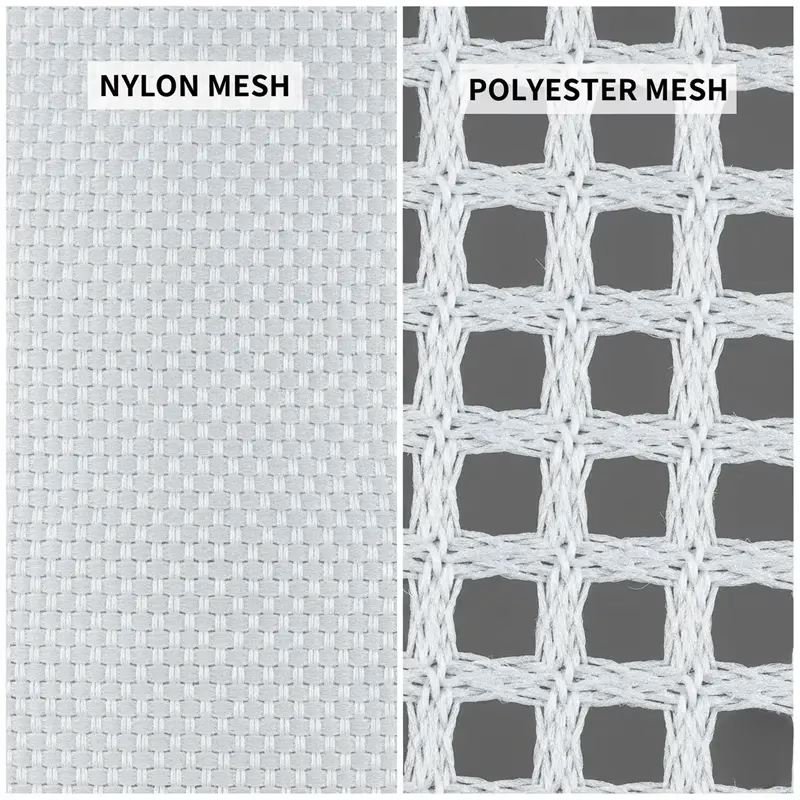

The fabric composition of your laundry nets determines how well they protect delicate items and how long they’ll serve your household or business. Both nylon and polyester dominate the market, but their molecular structures create distinct performance characteristics.

Nylon mesh consists of synthetic polymers formed through a condensation reaction. This creates long chains of molecules that give nylon its signature elasticity and strength. The material first gained popularity in the 1940s for military applications, proving its durability under extreme conditions. Today’s nylon mesh maintains these robust qualities while offering the fine weave necessary for protecting delicates.

Polyester mesh, on the other hand, emerges from petroleum-based products through a different chemical process. The resulting fibers resist shrinking and maintain their shape better than many alternatives. Polyester’s structure makes it naturally hydrophobic, meaning it repels water rather than absorbing it. This characteristic affects both washing performance and drying time.

The weave density matters as much as the material itself. Tighter weaves offer better protection but reduce water flow. Looser weaves allow better circulation but might let small items escape. Most quality manufacturers balance these factors, creating meshes with optimal openings—typically between 1-3 millimeters—that protect while allowing proper water and detergent circulation.

Temperature tolerance varies significantly between materials. Nylon begins to lose integrity around 175°F (79°C), while polyester withstands temperatures up to 300°F (149°C). This difference becomes crucial when washing items requiring hot water sanitization or when bags accidentally end up in high-heat dryer cycles.

Nylon Mesh Laundry Sacks: Strength Meets Flexibility

Nylon brings remarkable tensile strength to the laundry room. A standard nylon net bag for laundry can withstand pulling forces exceeding 50 pounds without tearing—impressive for such lightweight material. This strength translates directly to longevity when properly maintained.

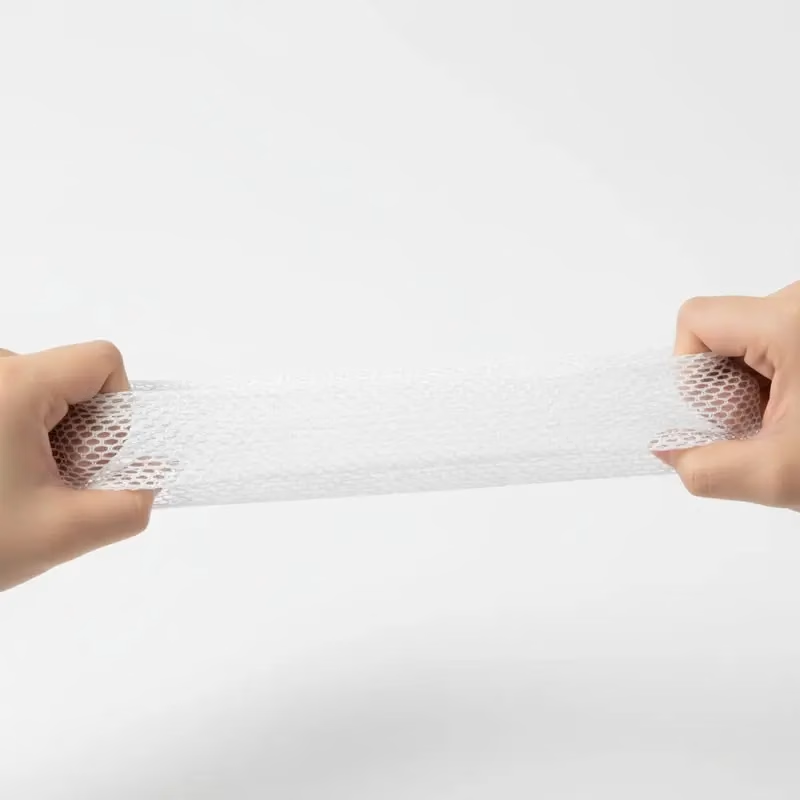

The elasticity of nylon allows bags to accommodate varying loads without permanent stretching. You can stuff a bulky sweater into a medium-sized bag, and the material will return to its original shape after washing. This flexibility proves especially valuable for households washing items of different sizes and shapes regularly.

Professional laundry services often prefer nylon for its abrasion resistance. The material withstands repeated friction against washing machine drums without developing holes or thin spots. Industrial testing shows nylon mesh maintains integrity through 500+ wash cycles when used within recommended temperature ranges.

However, nylon has limitations. The material absorbs moisture—up to 8% of its weight—which can lead to longer drying times. In humid environments, nylon bags might develop musty odors if not dried thoroughly. The material also yellows over time when exposed to sunlight or bleach, though this discoloration doesn’t affect performance.

Cost considerations favor nylon for budget-conscious buyers. Manufacturing processes for nylon mesh have been refined over decades, making it generally 15-20% less expensive than comparable polyester options. For businesses purchasing bags in bulk, this price difference adds up significantly.

Comparison Table: Nylon Mesh Properties

| Property | Performance Rating | Typical Lifespan | Best For |

|---|---|---|---|

| Tensile Strength | 9/10 | 2-3 years heavy use | Heavy items, frequent washing |

| Elasticity | 10/10 | Maintains throughout life | Variable load sizes |

| Heat Resistance | 6/10 | Reduced at high temps | Cold to warm wash only |

| Moisture Management | 5/10 | Slower drying | Low-humidity environments |

| Cost Effectiveness | 9/10 | Excellent value | Budget-conscious buyers |

Polyester Mesh: The Temperature-Resistant Champion

Polyester mesh laundry sacks excel where nylon struggles—specifically in high-temperature environments. The material maintains structural integrity through hot water washes and accidental dryer exposure that would damage nylon alternatives. This resilience makes polyester ideal for items requiring sanitization or commercial laundry operations using industrial equipment.

The hydrophobic nature of polyester creates practical advantages. Water beads off the surface rather than soaking in, resulting in faster drying times. A polyester bag air-dries completely in half the time of its nylon counterpart. This quick-drying property prevents mildew growth and eliminates the musty smell that sometimes plagues other materials.

Color retention ranks among polyester’s strongest features. While nylon yellows and fades, polyester maintains its appearance through years of use. The material resists both chlorine bleach and UV radiation, keeping bags looking newer longer. For businesses where professional appearance matters, this aesthetic durability proves valuable.

Polyester’s dimensional stability means bags keep their original size and shape regardless of washing conditions. No shrinking. This predictability helps when organizing laundry systems where specific bag sizes serve designated purposes. Small mesh laundry bags for delicates stay small, maintaining consistent sorting systems.

The material does have drawbacks. Polyester lacks nylon’s stretch, making it less forgiving when overfilled. The lower elasticity can lead to zipper strain when bags are packed too full. Additionally, polyester’s smooth surface can feel slippery when wet, potentially making bags harder to handle during transfers between washer and dryer.

Environmental considerations increasingly favor polyester for sustainability-minded consumers. Recycled polyester, made from post-consumer plastic bottles, offers identical performance to virgin polyester while reducing plastic waste. Many manufacturers now offer eco-friendly polyester options that appeal to environmentally conscious buyers.

Direct Comparison: Performance Metrics That Matter

Understanding how these materials perform across various metrics helps make informed purchasing decisions. Real-world testing reveals surprising differences that affect daily use and long-term value.

Durability Comparison Table

| Test Category | Nylon Performance | Polyester Performance | Winner |

|---|---|---|---|

| Tear Resistance (lbs of force) | 52 lbs | 48 lbs | Nylon |

| Heat Tolerance (max safe temp) | 175°F | 300°F | Polyester |

| UV Resistance (hours before degradation) | 200 hours | 500+ hours | Polyester |

| Stretch Recovery (% return to original) | 98% | 92% | Nylon |

| Abrasion Cycles (before visible wear) | 15,000 | 12,000 | Nylon |

| Water Absorption (% of weight) | 8% | 0.4% | Polyester |

| Chemical Resistance (bleach tolerance) | Low | High | Polyester |

Load capacity testing shows interesting results. Nylon bags handle overloading better due to their stretch, accommodating 20% more volume than rated capacity without damage. Polyester bags maintain their rated capacity precisely but may experience zipper failure if overstuffed. This difference matters for users who occasionally push capacity limits.

Washing performance varies by water temperature. In cold water (60°F), both materials perform identically. At 105°F—typical warm wash temperature—polyester shows slight advantages in maintaining mesh structure. Above 140°F, polyester clearly outperforms, while nylon begins showing stress signs.

The longevity equation involves multiple factors. Under ideal conditions (cold water, gentle cycle, air drying), nylon bags last 3-4 years with regular use. Polyester bags under the same conditions last 4-5 years. However, add hot water washing and machine drying, and polyester’s lifespan advantage increases dramatically—often doubling nylon’s usable life.

Cost-per-use calculations reveal surprising insights. While nylon costs less initially, polyester’s extended lifespan often makes it more economical long-term. A $8 polyester bag lasting four years costs $0.005 per use (assuming weekly washing). A $6 nylon bag lasting two years costs $0.006 per use—20% more expensive over time.

Choosing the Right Mesh Laundry Sack for Your Needs

Selection criteria depend heavily on specific use cases. Household users face different challenges than commercial operations, and understanding these distinctions guides better purchasing decisions.

For household use, consider your washing habits first. Families washing primarily in cold water with occasional warm cycles find nylon perfectly adequate. The material’s lower cost and excellent stretch make it ideal for variable loads—from a single delicate blouse to multiple lightweight sweaters. Nylon washing bags for delicates handle the typical household’s diverse laundry needs effectively.

Commercial environments demand different considerations. Hotels, hospitals, and laundromats subject bags to intensive use cycles and higher temperatures. Polyester becomes the clear choice here. The material withstands industrial washing equipment, repeated high-temperature sanitization, and constant use without premature failure. The higher initial investment pays dividends through reduced replacement frequency.

Specialty applications require targeted choices. Lingerie and hosiery benefit from nylon’s gentle stretch, which prevents stress on delicate elastics. Athletic wear and synthetic performance fabrics wash better in polyester bags that won’t retain odors. Vintage or antique textiles need the softest possible mesh—often ultra-fine nylon—to prevent snags on fragile fibers.

Size selection affects material choice. Small mesh laundry bags for delicates work well in either material since they handle lighter loads. Large bags carrying heavy items like sneakers or thick sweaters benefit from nylon’s superior tear resistance. Medium bags see the most versatility, performing well in either material depending on primary use.

Multi-bag systems often combine both materials strategically. Professional organizers recommend polyester for frequently used bags handling everyday items and nylon for specialty bags used occasionally. This hybrid approach maximizes value while ensuring each bag type serves its optimal purpose.

Consider linking to your laundry bag set collection for customers wanting variety.

Maintenance Tips: Maximizing Your Mesh Laundry Sack Lifespan

Proper care dramatically extends the lifespan of your mesh laundry sacks, regardless of whether they’re made from nylon or polyester. With a few simple maintenance practices, users can easily double or even triple the expected service life of their bags, making even budget options a smart long-term investment.

1. Keep Your Laundry Bags Clean

Regular cleaning prevents buildup that weakens mesh fibers over time. Run empty laundry bags through a standard wash cycle once a month using warm water and mild detergent. This process removes lint, detergent residue, and fabric softener buildup that can clog mesh openings and restrict water flow.

Avoid using bleach on nylon mesh bags, as it can degrade fibers. However, polyester mesh laundry bags can tolerate bleach occasionally for deep cleaning — just use it sparingly to maintain fabric integrity.

2. Maintain and Protect Zippers

Zippers are often the first component to fail. To prevent premature wear, lubricate zippers quarterly using soap, candle wax, or a specialized zipper lubricant. Always keep zippers fully closed during washing to reduce snagging and stress.

If zippers start sticking consistently, replace the bag promptly. Forcing a jammed zipper can tear the mesh and ruin the entire bag.

3. Store Properly Between Uses

Storage plays a bigger role than most users realize. After washing, hang bags to dry completely to prevent mildew or odor buildup. Store them in a cool, dry location away from direct sunlight to protect the fibers from UV damage.

Avoid stacking heavy items on top of your mesh laundry bags, as compression can create permanent creases that weaken the fabric. Many users dedicate a specific drawer, hook, or basket for storage to keep bags organized and in good condition.

4. Manage Load Distribution

How you fill your laundry bag affects its longevity. Overloading causes unnecessary stress on seams and mesh fibers. Aim to fill each bag to no more than 75% of capacity, allowing proper water circulation and even fabric movement during washing.

Distribute weight evenly — avoid bunching items in one corner. For heavy items such as jeans, towels, or sneakers, place them in the center of the bag to minimize corner strain and prevent mesh tearing.

5. Watch Washing Temperatures

Even though polyester mesh is heat resistant, cooler water temperatures still extend lifespan. Always check care labels and use the lowest effective temperature setting for your laundry type.

Reserve hot water or sanitize cycles for items that truly require them, such as heavily soiled linens or medical fabrics. This practice not only saves energy but also reduces fiber stress and prevents premature wear on both nylon and polyester laundry bags.

6. Inspect and Repair Regularly

Routine inspections can prevent small issues from becoming big problems. Examine your bags monthly for holes, weakened seams, or zipper wear.

Small tears can often be repaired using a simple needle and thread — a quick fix that can extend the life of your durable mesh laundry bag by months or even years. Reinforce high-stress areas proactively to prevent catastrophic failures that could damage both the bag and the delicate fabrics inside.

Key Takeaway: Small Habits, Big Impact

A well-maintained mesh laundry sack not only protects your clothes but also reduces replacement costs and environmental waste. Consistent cleaning, mindful loading, and proper storage all contribute to keeping your laundry system running efficiently.

Whether you use nylon or polyester mesh laundry bags, these simple care routines ensure they stay strong, reliable, and ready for every wash cycle.

Seasonal Maintenance Schedule

| Season | Maintenance Task | Frequency | Materials Needed |

|---|---|---|---|

| Spring | Deep clean all bags | Once | Mild detergent, warm water |

| Summer | Check for sun damage | Monthly | Visual inspection |

| Fall | Lubricate zippers | Once | Soap or zipper lubricant |

| Winter | Inspect for holes/tears | Monthly | Needle and thread for repairs |

Environmental Impact: Sustainability Considerations

The environmental footprint of laundry accessories rarely gets attention, yet choices here affect both immediate surroundings and broader ecological systems. Understanding these impacts helps align purchasing decisions with environmental values.

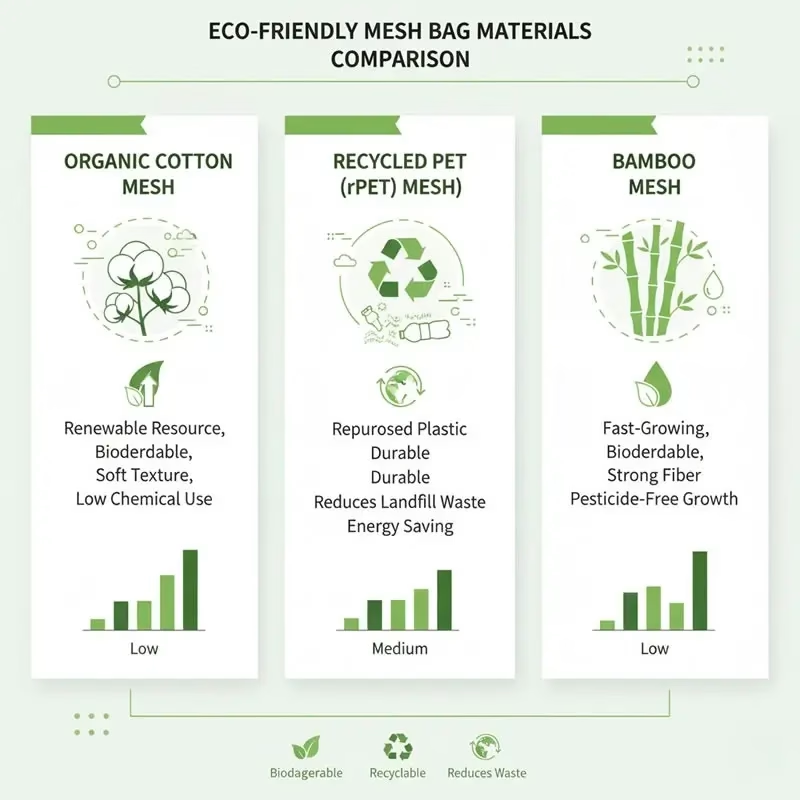

Manufacturing processes differ significantly between materials. Nylon production requires more energy and generates more greenhouse gases than polyester manufacturing. However, nylon’s biodegradability timeline—30-40 years—beats polyester’s 200+ years. This creates a complex environmental equation without clear winners.

Microplastic release during washing affects both materials but at different rates. Studies show polyester releases 1.5 times more microplastics per wash than nylon. These microscopic fibers pass through water treatment systems, eventually reaching oceans. Using laundry nets actually helps by trapping some microfibers that would otherwise escape from clothes directly.

Recycling options increasingly favor polyester. Many facilities accept polyester mesh bags for recycling, while nylon recycling remains limited. Some manufacturers now offer take-back programs, collecting worn bags for proper recycling or repurposing. Check our premium polyester options for recyclable choices.

The durability factor significantly impacts environmental calculations. A longer-lasting bag means fewer replacements, less manufacturing, and reduced waste. Polyester’s extended lifespan often offsets its slower degradation rate. One polyester bag lasting five years creates less waste than two or three nylon replacements over the same period.

Energy usage during the product lifecycle varies by user behavior. Polyester’s quick-drying nature reduces energy consumption when machine drying. Its resistance to high temperatures means less frequent replacement due to heat damage. These factors compound over years of use, creating measurable energy savings.

Eco-friendly alternatives continue emerging. Recycled polyester from ocean plastics, organic cotton mesh, and bamboo fiber options provide environmentally conscious choices. While these typically cost more, they appeal to consumers prioritizing sustainability. Manufacturing innovations promise even better options in coming years.

Professional Applications: Commercial and Industrial Use

Large-scale laundry operations operate under demanding conditions far beyond the needs of typical households. Hotels, hospitals, athletic facilities, manufacturing plants, and industrial laundries all require heavy-duty laundry bags that can handle constant high-volume processing, exposure to chemicals, and frequent high-heat cycles.

In these professional settings, polyester mesh laundry bags consistently outperform nylon due to their durability, chemical resistance, and temperature tolerance.

Hotels: Prioritizing Appearance and Operational Efficiency

In the hospitality industry, presentation and speed are everything. Commercial laundry bags for hotels must retain their professional look even after hundreds of washes and bleaching cycles. Polyester bags maintain their crisp white appearance, a vital factor in preserving brand image and hygiene standards.

Their quick-drying properties help accelerate the laundry cycle, improving turnaround time for linens and towels. Many hotels report a 40% longer lifespan with polyester mesh bags compared to nylon alternatives, particularly under high-temperature wash programs.

Healthcare Facilities: Maintaining Hygiene and Infection Control

Healthcare laundries must meet the strictest sanitization standards. Industrial polyester laundry bags can withstand autoclave sterilization and high-temperature washing, both essential for infection prevention.

Unlike nylon, polyester does not trap moisture or harbor bacteria in its fibers, ensuring each use remains hygienic. Hospitals and clinics also benefit from color-coded laundry systems—made possible by polyester’s superior dye and color retention—to separate linens by department and use type.

Athletic and Sports Facilities: Odor Resistance and Durability

Sports teams, gyms, and athletic centers face heavy soil loads and odor challenges. Polyester’s non-absorbent structure prevents sweat and odor buildup, making it ideal for washing uniforms, towels, and training gear.

These heavy-duty mesh laundry bags also handle enzyme-based detergents and antimicrobial treatments without degrading. Many athletic programs report significant reductions in equipment replacement costs after switching from nylon to quality polyester laundry bags.

Manufacturing and Industrial Laundries: Chemical Resistance and Process Control

In manufacturing environments, mesh laundry bags are often used beyond fabrics — for parts washing and component protection. Polyester’s chemical resistance makes it the superior choice, as it withstands industrial solvents and degreasers that would weaken or dissolve nylon.

Consistent mesh size and strength also ensure reliable drainage, predictable drying rates, and consistent cleaning performance, helping maintain process quality and safety standards.

Rental Services and Uniform Management: Tracking and Identification

Linen rental and uniform management companies depend on accurate tracking to prevent loss and improve efficiency. Polyester is ideal for these systems because it accepts barcodes, heat-sealed labels, and printed IDs far better than nylon.

Its dimensional stability keeps labels intact and readable even after hundreds of wash cycles, enabling smooth logistics, efficient sorting, and reduced inventory loss.

Commercial Cost Efficiency: Long-Term Return on Investment

While polyester laundry bags may cost more upfront, the return on investment (ROI) quickly becomes clear in commercial use. On average, polyester models pay for themselves within 18 months thanks to lower replacement rates and longer lifespans.

Additional savings come from faster drying, reduced labor time, and fewer failures during operation. Over a three-year cycle, most facilities report 25–30% lower total ownership costs when using polyester instead of budget nylon alternatives.

Key Takeaway: Polyester Dominates in Professional Settings

For any high-volume or high-temperature laundry system, polyester mesh laundry bags offer superior durability, hygiene, and overall value. From hotels and hospitals to gyms and factories, their resilience under pressure makes them the preferred choice for commercial and industrial laundry operations worldwide.

Commercial Use Comparison Table

| Industry | Primary Concern | Recommended Material | Expected Lifespan | ROI Timeline |

|---|---|---|---|---|

| Hotels | Appearance, bleach resistance | Polyester | 3-4 years | 12 months |

| Hospitals | Sanitization, durability | Polyester | 4-5 years | 18 months |

| Athletic Facilities | Odor resistance, heavy loads | Polyester | 2-3 years | 8 months |

| Manufacturing | Chemical resistance | Polyester | 5+ years | 24 months |

| Rental Services | Tracking, identification | Polyester | 3-4 years | 15 months |

Making Your Final Decision: Practical Selection Guide

The choice between nylon and polyester ultimately depends on individual circumstances. No universal answer fits every situation, but systematic evaluation helps identify optimal choices.

Step 1: Assess Your Primary Use Case

Start by assessing your main laundry needs. Household users washing mixed loads in cold water often find nylon perfectly suitable. The cost savings and adequate performance make it the practical choice. Families with young children generating frequent loads benefit from nylon’s flexibility when bags get overstuffed accidentally.

Step 2: Match Material to Equipment and Washing Habits

Consider your washing machines and habits. High-efficiency washers with sanitize cycles demand polyester’s superior heat resistance. Traditional top-loaders using cold water work fine with either material. Dryer users should choose polyester regardless of washing temperature—accidental high-heat exposure won’t cause damage.

Step 3: Balance Budget and Longevity

Evaluate your budget holistically. Initial cost matters less than total ownership cost. Calculate replacement frequency based on your washing patterns. Heavy users washing daily might find polyester’s longevity justifies the premium. Occasional users washing delicates weekly might never encounter nylon’s limitations.

Step 4: Factor in Special Requirements

Allergy sufferers benefit from polyester’s antimicrobial options. Eco-conscious consumers might prefer recycled polyester despite higher costs. For professional environments, polyester’s ability to maintain its appearance makes it ideal. Ultimately, specific needs often override general recommendations.

Step 5: Test Before Bulk Purchases

Before committing to large orders, buy one or two bags of each material for trial. Note differences in performance under your specific conditions. This hands-on experience often reveals preferences that no specification sheet can predict.

Step 6: Mix and Match Strategically

Remember that a hybrid approach works well. Use polyester for frequently washed everyday items and nylon for occasional special-care loads. This strategy maximizes both value and lifespan without compromising performance.

Material Longevity: Nylon vs. Polyester

The longevity question—which material lasts longer—has a clear answer: polyester generally outperforms nylon under demanding conditions. However, nylon still provides excellent service life when used properly. Smart selection based on your washing environment ensures satisfaction regardless of the choice.

Browse our complete selection to find perfect matches for your needs.

Quality and Construction: The Hidden Factor

Material choice matters, but construction quality often matters more. A well-constructed nylon bag from a reputable manufacturer can outlast a low-grade polyester alternative. Look for reinforced seams, durable zippers, and appropriate mesh density—these details significantly affect lifespan and performance.

1. How many wash cycles can a quality polyester laundry mesh sack typically withstand?

Quality polyester sacks last 800–1000 cycles at home; commercial-grade versions can exceed 1500 cycles with proper care.

2. What testing standards should buyers check for bulk orders?

Look for AATCC and ISO 9001 compliance, 1–3mm mesh density, and tensile strength above 45 lbs. Always request test reports for large orders.

3. Can nylon and polyester mesh bags be washed together?

Yes. Keep temps below 175°F for nylon, manage drying times, and color-code bags to prevent mix-ups.

4. What warranty terms show product confidence?

Good brands offer 12–24 month warranties covering defects, seam or zipper issues, and normal wear—ask for written terms.

5. How do antimicrobial polyester bags compare for healthcare use?

They cut bacteria by 99.9%, last 300+ washes, and cost about 20–25% more, but improve infection control and hygiene.

Partner with a Trusted Manufacturer

For over a decade, we’ve manufactured premium mesh laundry sacks that meet the demanding requirements of customers worldwide. Our direct manufacturing capability means competitive pricing without compromising quality. Whether you need specialized washing nets for delicate garments or durable polyester bags for commercial operations, we deliver solutions tailored to your specifications.

Contact our team today to discuss custom designs, bulk orders, or OEM partnerships. With customers across Europe, North America, and Asia trusting our products, you can be confident in choosing a proven manufacturing partner committed to quality, sustainability, and long-term value.