Dirty shoes happen—rainy days, gym sessions, playground runs. Tossing them straight into the washer can scuff the drum, wreck the foam, and rattle like a rock concert. The fix? A shoe bag for washing machine use. It cushions impact, keeps parts together, and improves water flow for a more even clean. Below you’ll find a simple process you can follow today, plus a buying guide for choosing the right shoe washing bag for your team or product line.

Why a shoe bag for washing machine matters

Think of a shoe bag for washing machine as a buffer and organizer. It keeps shoelaces contained, separates shoes from delicate garments, and reduces banging against the drum. The result? Lower impact, less noise, and fewer scratches on both shoes and machine.

A mesh bag for washing shoes also improves rinse performance. Water and detergent can circulate through the mesh, lifting soil evenly. Compared to washing shoes loose, you often get fewer scuffs and better shape retention.

Key advantages:

Protection: Foam midsoles, toe caps, and eyelets stay safer.

Noise control: Less clatter, fewer mid-cycle surprises.

Hygiene: Keeps debris (grit, mud) contained.

Organization: Wash laces and insoles together without losing them.

When not to machine-wash:

Leather dress shoes, suede, or shoes with glued-on adornments that can detach.

Shoes labeled “Do Not Wash” or “Dry Clean Only.”

Old footwear with cracked midsoles or failing adhesives.

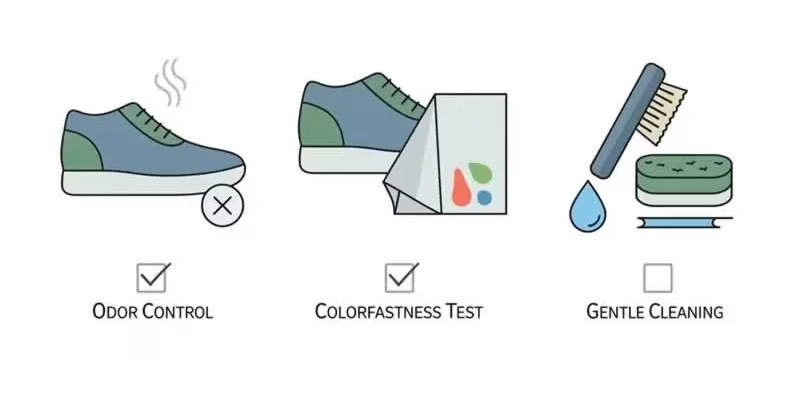

Pre-wash checklist for clean, safe results

A few minutes of prep can save you hours of frustration. Follow this quick list.

1) Read the care label

Look for washing symbols. If you see a hand-wash symbol or a crossed-out machine icon, skip the washer. When in doubt, spot-clean.

Helpful reference for symbol meanings: Laundry care symbols

2) Dry brush and knock out grit

Tap soles together outside. Use a soft brush to remove mud and sand. Less sediment in the bag means fewer scratches and better cleaning.

3) Remove laces and insoles

Place them in a small mesh pouch. This improves contact with water and helps them dry faster. It also prevents lace tangles.

4) Pre-treat stains

Use a mild, color-safe stain remover on scuffs and oily marks. Test on an inside seam first. Avoid bleach on colored or synthetic uppers.

5) Load with support

Put shoes in a shoe bag for washer. Add two or three towels as shock absorbers. Choose light-colored towels for light shoes.

6) Choose the right detergent

A small dose of liquid detergent works best. Powder can clump. If chemical sensitivity matters, check products with the EPA Safer Choice label.

Step-by-step: machine-wash your shoes correctly

Follow these simple steps to reduce risk and get a solid clean.

Step 1: Set the cycle

Use cold or warm water, gentle cycle, and low spin. High heat and heavy spin can warp adhesives and midsoles.

Step 2: Bag and balance

Place shoes in a shoe washing bag. Zip fully. Add your towel “shock absorbers” to balance the load and quiet the wash.

Step 3: Dose light

Use about half your usual detergent amount. More soap doesn’t mean cleaner shoes—it often means residue.

Step 4: Optional deodorizing

A tablespoon of baking soda in the drum (not in the bag) helps with odor. Avoid liquid fabric softener; it can coat fibers and reduce breathability.

Step 5: Run the rinse

If the water looks soapy at the door or the shoes feel slick post-wash, run an extra rinse.

Step 6: Inspect

Check seams, glue lines, and colorfastness. If the fabric looks stressed, skip a second wash and air dry.

Internal link for buyers and teams: Want purpose-built options? Explore our washing bags for shoes.

Drying and aftercare — keep shape and avoid heat

Skip the dryer. High heat can melt adhesives, warp foam, and shrink uppers.

Air-drying routine:

Press shoes gently with a towel to remove excess water.

Stuff with clean paper (not newspaper ink) or unbleached packing paper. Replace once as it soaks.

Dry in a shaded, ventilated spot. Direct sun can yellow white soles and fade color.

Dry laces and insoles flat.

After drying, brush fibers to lift the nap on mesh or knit uppers.

Sanitary considerations:

If you’re washing after illness or heavy contamination, regular laundering with detergent in warm water is usually enough. For general guidance on laundry hygiene,

Shoe bag vs mesh bag vs pillowcase: which should you use?

Not all “protection” solutions are equal. Here’s a quick comparison.

| Option | Best for | Protection | Water Flow | Noise Control | Durability | Notes |

|---|---|---|---|---|---|---|

| Dedicated shoe bag for washing machine | Regular sneaker care, facilities, teams | High (structured walls, foam pads optional) | Excellent (engineered mesh) | Strong | High | Designed for shoes; zips secure; compartments keep pairs aligned |

| General mesh bag for washing shoes | Light-duty or occasional washes | Medium | Excellent | Good | Medium | Works well but may lack structure for heavy shoes |

| Pillowcase hack | Last-resort home fix | Low | Poor–Medium | Low | Low | Can open mid-wash; uneven results; not recommended for repeated use |

The winner? A shoe bag for washer that’s built for repeated cycles. Look for structure, strong zippers, and abrasion-resistant mesh.

Buying guide: choose the right shoe washing bag for your line

You might be outfitting a gym, a care facility, or a retail brand. Choosing the right shoe washing bag saves returns and extends product life.

Material matters:

Polyester hex or honeycomb mesh: Balanced airflow and durability.

Nylon mesh: Tough and flexible; ideal for heavier shoes.

Foam padding panels: Absorb impact; check for closed-cell foam that dries quickly.

Reinforced binding: Protects edges and seams.

Mesh spec:

Aperture size should allow water flow but stop lace tips and eyelets from catching.

Too tight? Rinse suffers. Too open? Scuffs increase.

Closures:

Hidden coil zippers with zipper garages reduce snagging.

Hook-and-loop is quick but can snag fabrics.

Locking sliders prevent mid-wash opening.

Structure:

Single-compartment bags for general use.

Dual-compartment or shoe-separating cradles for better shape control.

Flat vs. boxy bags: Boxy designs keep toe caps from crushing.

Stitching:

Double-stitched seams or overlock reinforcement at stress points.

Bar tacks at zipper ends to prevent splits.

Compliance and testing:

Ask for materials that can pass REACH and related standards. Document it.

Colorfastness and abrasion tests help prevent dye transfer issues.

Sizes:

Small (kids, women’s slim trainers)

Medium (standard running shoes)

Large (bulky sneakers, work shoes)

Branding & packaging:

Heat-transfer logos or woven labels that resist wash cycles.

Retail-ready boxes or polybags with clear usage icons.

Manufacturing confidence:

Founded in 2014, our team designs and produces laundry mesh bags, washing bags, laundry baskets, storage boxes, and more. With six years of experience serving Europe, North America, South America, Korea, and Japan, we support OEM orders and customized designs. Our eco-friendly raw materials are selected to pass REACH and related tests. Need a custom shoe bag for washing machine with your specs? We can help.

Troubleshooting and pro tips

Shoes still smell?

Sprinkle baking soda inside overnight.

Wash insoles separately in a small mesh pouch.

Sunshine (brief, indirect) helps, but avoid long exposure to prevent yellowing.

Yellowing on white soles?

Use a non-bleach whitening cleaner designed for rubber.

Avoid chlorine bleach on synthetics; it can oxidize and worsen yellowing.

Color bleed risk?

Test with a damp white cloth before washing.

Wash dark shoes with dark towels.

Squeaky shoes after drying?

Sprinkle a bit of cornstarch under the insole.

Ensure shoes are fully dry before wear.

Need a deeper clean?

Pre-soak in cool water with a small amount of detergent for 20 minutes before the machine cycle.

Consider a second rinse to remove residue.

Sustainability and maintenance

A good mesh bag for washing shoes is reusable and protective, cutting down on damaged returns and wasted materials.

Lower impact tips:

Wash shoes in full, balanced loads to reduce water and energy per item.

Favor cold or warm cycles over hot.

Choose detergents on the EPA Safer Choice list to limit harsh chemicals.

Air dry instead of tumble dry.

Bag care:

Rinse the shoe bag after muddy washes.

Air dry the bag fully to protect the mesh and zipper.

Store flat or hang to avoid creasing the structure.

Before you start your next wash

Machine-washing shoes doesn’t have to be risky. Prep smart. Use a shoe bag for washing machine to cushion and contain. Select a gentle cycle, light detergent, and air-dry with care. For teams and buyers, pick bags with reinforced seams, reliable zippers, and mesh that balances flow and protection. That’s the path to clean shoes and fewer returns.

We design and manufacture shoe washing bags and other laundry solutions with eco-friendly materials and documented testing. Ready to spec your own?

FAQs for professional buyers

1) What’s the typical MOQ for a custom shoe washing bag?

MOQs vary by material and size, but most programs start around a few hundred units. Tell us your size mix and branding needs—MOQ scales with complexity.

2) Can you certify materials to pass REACH and related tests?

Yes. Our eco-friendly raw materials are selected to pass REACH and other relevant tests. We can provide documentation with your PO.

3) Do you offer multiple mesh densities and foam options?

We do. Choose from polyester or nylon meshes in different apertures, with or without foam padding. We’ll recommend specs based on shoe weight and intended use.

4) What closure styles can we select?

Common choices include hidden coil zippers with zipper garages, locking sliders, or hook-and-loop. For high-cycle use, we suggest locking zippers plus bar-tack reinforcement.

5) Can you handle OEM branding and retail packaging?

Absolutely. We support heat-transfer logos, woven labels, and retail-ready boxes or polybags. We’ll align packaging with your channel needs.

We’re the direct manufacturer—founded in 2014—with global customers and OEM capability. Need a custom shoe bag for washing machine program or a sample set for testing? Request a quote today and let’s build the right bag for your line.