Ever pulled a snagged bra strap or pilled knit out of the washer and wondered, “Could this have been avoided?” That’s where Mesh Laundry Bags step in. Choose the wrong mesh, and you’ll trap dirt, tangle straps, or slow drying. Pick the right one, and you protect fibers, keep small parts safe, and still get a thorough clean. In the next few minutes, you’ll learn the simple rules for choosing fine vs coarse mesh—so your clothes last longer, your returns drop, and your laundry workflow runs smooth.

What Are Mesh Laundry Bags?

Mesh Laundry Bags are protective pouches made from breathable knit or woven fabric (usually polyester or nylon). They act like a shield between garments and the drum. They also keep small parts—hooks, pads, removable inserts—contained. In short, they’re a simple tool that stops most wash-day mishaps without stopping water and detergent flow.

Why mesh matters:

Water and detergent must move freely.

Soil must escape the bag.

Fibers must avoid harsh friction and snag points.

The whole trick is matching mesh size to what you’re washing.

Fine vs Coarse Mesh Laundry Bags: Quick Overview

Let’s get you a snapshot before the deep dive.

Comparison Table 1: Fine vs Coarse Mesh

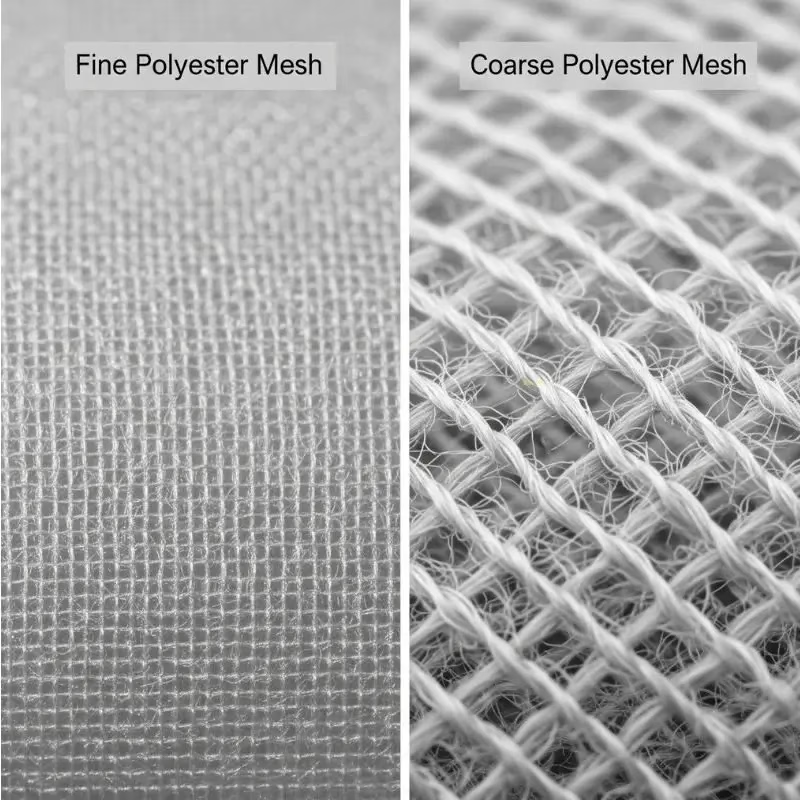

| Attribute | Fine Mesh Laundry Bag | Coarse Mesh Laundry Bag |

|---|---|---|

| Opening size (approx.) | ~0.5–2.0 mm | ~2–5 mm |

| Best for | Lingerie, hosiery, delicates, knits, silk, lace | Towels, denim, hoodies, sportswear, synthetic blends |

| Soil release | Lower (may trap lint/detergent if overloaded) | Higher (better flow and agitation) |

| Protection | Maximum fiber protection; reduces snagging | Moderate protection; stronger agitation |

| Drying | Slower | Faster |

| Tangling | Helps prevent tangling of straps | Good for bulk items; less likely to wrinkle traps |

| Risk if misused | Under-cleaning or residue buildup | Surface abrasion on delicate fibers |

| Typical shapes | Flat pouches, small cylinders | Larger pouches, cubes, cylindrical hampers |

Takeaway: If the fabric snags easily or sheds microfibers, go fine. If the item is rugged or soil-heavy, go coarse.

How Mesh Size Affects Wash Performance

Mesh size changes how water, detergent, and soil behave. Here’s how.

Agitation & Flow

Coarse mesh lets the drum’s movement “work” the fabric more, helping soil release. Fine mesh softens that motion, which is good for protection but can reduce scrubbing action.

Lint & Particle Control

Fine mesh helps keep lint from cross-contaminating other garments and traps loose hooks or bra wires. Coarse mesh favors flushing—lint and suds pass through faster.

Detergent Rinse-Out

Coarse mesh makes rinsing easier. Fine mesh rinses well when you keep loads light and avoid over-filling the bag.

Drying Time

Bigger openings = more airflow = faster drying. Fine mesh can slow airflow, especially if the bag is packed.

Choosing Mesh Size by Fabric Type

When in doubt, match the bag to the most delicate material in the load.

Comparison Table 2: Fabric/Item vs Best Bag

| Fabric/Item | Risk | Best Mesh | Notes |

|---|---|---|---|

| Lace, silk, hosiery | Snagging, stretching | Fine mesh | Close zippers; wash light and cool. |

| Bras (underwire) | Hook snags, wire poke-through | Fine mesh (structured) | Use a structured cup bag if possible. |

| Knit sweaters | Pilling, snagging | Fine mesh | Turn inside out; slow spin. |

| Activewear (synthetics) | Odor, soil, micro-snag | Coarse mesh | Needs flushing; mild detergent. |

| Denim, workwear | Heavy soil, abrasion | Coarse mesh | Don’t overload; high-flow wash. |

| Towels | Lint transfer | Coarse mesh | Keep separate from delicates. |

| Baby items & small socks | Loss, tangle | Fine mesh | Zip fully; avoid overstuffing. |

Zippers, Seams, and Shapes: More Than Mesh

Mesh is step one. Build quality is what holds up over hundreds of cycles.

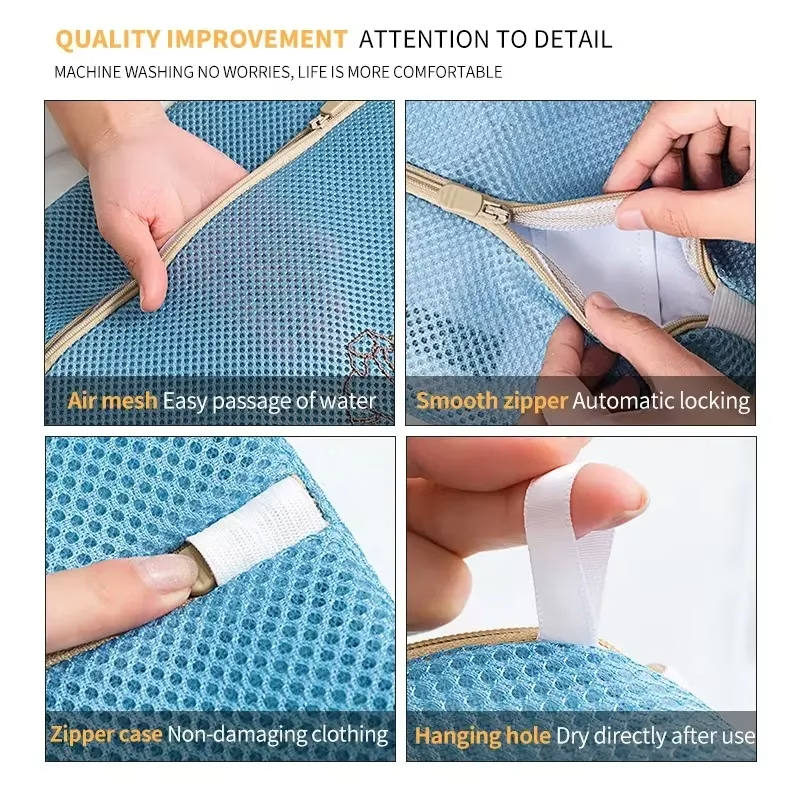

Zippers & Closures

Auto-lock zippers resist sliding open.

Zipper garages (fabric covers) stop scratching.

Hook-and-loop closures are quick but may catch lint; choose low-snag types.

Seams

Overlock or bound seams add strength.

Double stitching at stress points prevents early failure.

Shapes & Volumes

Flat pouches suit small delicates.

Cylinders/cubes suit towels and sports kits.

Gusseted designs hold shape in the drum to improve flow.

Quality, Compliance & Sustainability

If you buy at scale, you care about compliance and consistency. Materials matter.

Polyester mesh is durable, stable, and colorfast.

Nylon mesh is soft but can absorb more water.

Zippers should be nickel-safe and colorfast.

Dyes must resist bleed at standard wash temps.

Compliance: Our materials are environment‑friendly and designed to pass REACH-related evaluations. Curious about REACH? See the European Chemicals Agency overview: https://echa.europa.eu/regulations/reach/understanding-reach.

Sustainability tips:

Specify recycled polyester options when possible.

Choose durable stitching to extend lifespan.

Consolidate packaging; request flat-pack to reduce freight volume.

OEM & Customization Options

Established in 2014, our company designs and manufactures laundry mesh bags, washing bags, laundry baskets, storage boxes, and dirty clothes baskets for professional buyers worldwide—Europe, North America, South America, Korea, and Japan.

OEM & custom you can spec:

Mesh type: fine, medium, coarse, multi-layer.

Yarn & weight: polyester/nylon denier, GSM, elasticity.

Colors & labeling: heat-transfer logos, woven labels, barcodes.

Zippers: coil vs molded, pullers, zipper garages.

Shapes & sizes: flat, gusseted, cylinder, cube, structured bra bags.

Packaging: retail header cards, polybags, FSC cartons.

Testing: our environment‑friendly raw material is built to pass REACH-related and other relevant tests.

If you need a matched set (e.g., XS–XL), we’ll align colors, icons, and packing units to make SKU management easy.

Care, Maintenance & Lifespan

Treat the bag well and it’ll protect your garments for a long time.

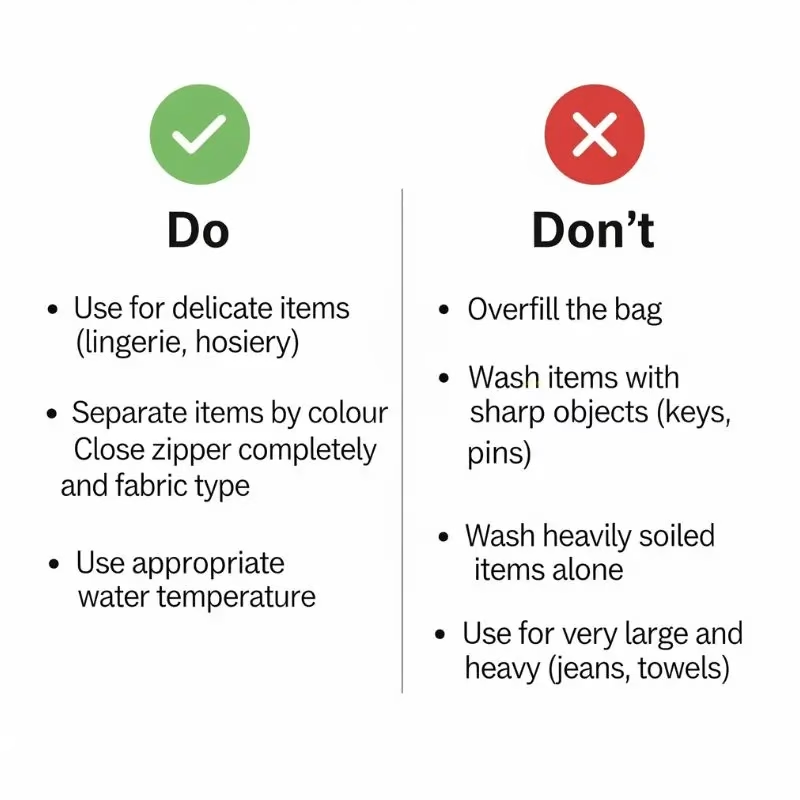

Close zippers before washing (and tuck pulls into garages).

Shake out lint post-wash; air dry the bag flat.

Avoid overloading. It stretches seams and shortens life.

Replace if holes enlarge or the zipper no longer locks.

Fine vs coarse lifespan: Fine mesh can show wear sooner if you push heavy loads. Coarse mesh usually lasts longer under bulk and higher spin speeds.

Cost of Ownership & Procurement Tips

Saving a few cents on unit price can cost more later.

Spec the mesh correctly. Returns due to snags or poor cleaning cost far more than a tiny price delta.

Confirm zipper quality. Auto-lock + garage reduces scratch claims.

Standardize sizes. Simplify reordering and pick‑pack.

Ask for carton optimization. Right folding and packing boosts container utilization.

Run a pilot. Test fine vs coarse mesh on your typical wash cycles before volume orders.

Lifecycle math (simple):

If a fine mesh bag prevents one damaged bra per 20 cycles, it’s paid for itself. A coarse mesh bag that cleans faster reduces reruns and energy use. Balance both across your assortment.

Common Mistakes & How to Avoid Them

Overstuffing the bag. Kills cleaning power.

Using coarse mesh for lace. Leads to snags and pilling.

Mixing towels with delicates in the same bag. Lint and abrasion will win.

Skipping the zipper garage. Drum scuffs show up fast.

Running high heat for elastic delicates. Stretch damage happens quickly.

Quick Decision Framework: Pick Your Mesh in 5 Steps

Identify the riskiest fabric. Lace > knits > synthetics > towels.

Choose mesh for the risk. Delicate = fine; rugged/soil-heavy = coarse.

Size the bag. 2/3 full at most, with room to move.

Select hardware. Auto-lock zipper + garage; reinforced seams.

Pilot and document. Note cycle settings and results to standardize.

Where to Source: Trusted Manufacturing Partner

We’re a professional manufacturer (est. 2014) with customers across Europe, North America, South America, Korea, and Japan. OEM orders welcome, custom designs available. Our environment‑friendly raw materials are developed to pass REACH-related and other relevant tests.

Explore our current models and request samples:

👉 Laundry Mesh Bag – Product Page

Care Symbols & Washing Settings—A Helpful Reminder

Match bag choice with care labels. If the tag shows a tub with a hand, keep it in fine mesh and a delicate cycle. If it’s a heavy-duty symbol, coarse mesh is usually safe.

For a quick refresher on laundry symbols, see: https://en.wikipedia.org/wiki/Laundry_symbol.

Final Steps

Fine mesh = protection for delicate fibers.

Coarse mesh = better flow for bulky or soil-heavy loads.

Build quality (zippers, seams) matters as much as mesh.

Plan capacity to keep cleaning strong and drying fast.

Specify and test before you scale up.

When you need a matched set for multiple categories—lingerie to towels—spec a mix: fine mesh for delicates, coarse mesh for rugged items. That’s the easiest way to cut damages and improve cleaning without changing your machines.

FAQs (for procurement, product, and purchasing teams)

1) How should I specify mesh in RFQs to avoid confusion?

List opening size (approx. mm), fabric material (polyester or nylon), weight (GSM), colorfastness needs, and zipper type (auto-lock with garage). Add seam method (overlock/bound), size tolerance, and packaging details per SKU.

2) What tests should I request for compliance?

Ask for material declarations to support REACH-related requirements, colorfastness tests, wash cycle durability, and zipper performance. If you sell in multiple regions, align with your retailer’s testing program.

3) What’s a practical assortment for retail sets?

A common 3–5 piece set: XS/S fine mesh (lingerie/socks), M fine mesh (knits), L coarse mesh (sportswear), XL coarse mesh (towels/hoodies), plus one structured bra bag. Keep icons and colors consistent for easy shelf read.

4) Can we add branding without hurting performance?

Yes—heat-transfer or woven label branding works well. Keep labels small and away from high-wear zones. Use colorfast inks and test at your target wash temps.

5) What’s the most common cause of returns with mesh bags?

Overfilling. It reduces cleaning power and stresses seams and zippers. Train users to fill only two‑thirds and to sort by fabric type.