Ever pulled a favorite bra or jersey from the washer and found snags or twisted straps? Ouch. That’s the moment you realize you need Mesh Laundry Bags. The right bag keeps delicates safe, prevents pilling, and even helps separate fabrics by load. But not all bags are built the same. Sizes, mesh gauge, fiber type, and zipper design all affect durability and wash results. Since 2014, we’ve manufactured laundry mesh bags at scale for buyers worldwide. We source eco-friendly materials that can pass REACH and related tests. Below, you’ll find the best picks for 2025, how to choose the right size, and what to spec for OEM orders.

Quick link: View standard options and request a quote here: laundry mesh bag

Best Mesh Laundry Bags

Looking for fast answers? Here’s a snapshot by use case:

Delicates & lingerie: Small to medium bag, fine mesh (smaller holes), nylon coil laundry bag with zipper and zipper garage.

Sweaters & knitwear: Large or XL, medium mesh, soft hand-feel, bound seams to reduce abrasion.

Activewear & sports kits: Medium to large, medium mesh for water flow, reinforced seams for frequent cycles.

Jeans & heavy garments: XL or jumbo, coarse mesh, heavy gauge zipper with auto-lock slider.

Bedding & linens: XL rectangle or cube-shaped set; look for bar-tacks at stress points.

Shoes & accessories: Structured cylinder or cube, double walls, foam ring optional.

Travel sets & assortments: 3–6 piece sets (S/M/L + specialty bra cylinder) for retail or welcome kits.

Why these make the cut: Good water flow, strong closures, and seams that survive 100+ cycles. They protect garments without slowing your laundry routine.

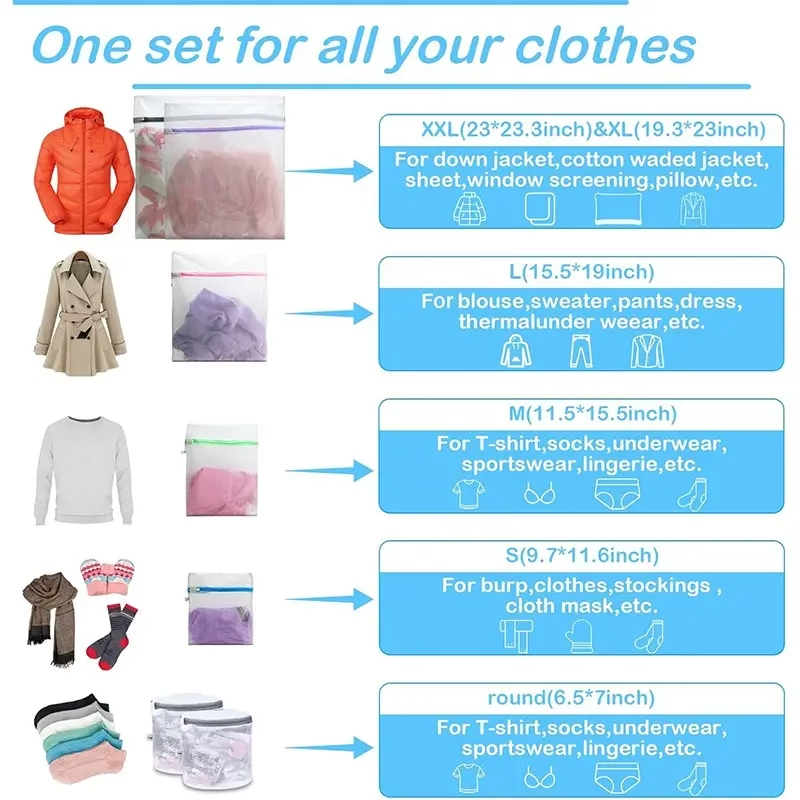

How to Choose Sizes for Mesh Laundry Bags

Size has a big impact on wash results. Overstuff a bag and water can’t circulate. Underfill it and items bunch up.

Basic rules of thumb:

Fill bags to about 2/3 capacity.

Leave room for water and detergent to move.

Match bag volume to garment weight, not just count.

Size & Use-Case Guide

| Size | Typical Dimensions | Suggested Load | Best For | Notes |

|---|---|---|---|---|

| Small (S) | 8″×12″ / 20×30 cm | 1–2 bras or 3–4 underwear | Delicates | Fine mesh recommended |

| Medium (M) | 12″×16″ / 30×40 cm | 2–3 T-shirts, light activewear | Everyday items | Great “catch-all” size |

| Large (L) | 16″×20″ / 40×50 cm | 1 sweater, 1–2 leggings | Knitwear & sets | Prevents stretching |

| XL | 20″×24″ / 50×60 cm | Jeans, hoodies, towels | Heavy garments | Choose stronger zipper |

| Jumbo | 24″×28″+ / 60×70+ cm | Bedding or bulk loads | Linens & duvet covers | Look for bar-tacked corners |

Tip: For machine-balanced loads, use two medium bags instead of one jumbo when possible. It reduces twisting.

Materials for Mesh Laundry Bags: Polyester vs. Nylon

Materials set the tone for feel, strength, and life cycle. Most Mesh Laundry Bags use either polyester (PET) or nylon (PA).

Polyester (PET): Holds shape, resists stretching, dries fast, cost-effective. Great for most loads.

Nylon (PA): Smooth hand-feel; often used in fine mesh for delicates. Slightly higher cost; great abrasion resistance.

Recycled PET: Same performance with a lower footprint; ideal for sustainability programs.

Cotton mesh: Breathable for storage, but not ideal for heavy wash cycles; can shrink and dry slower.

Material & Build Comparison

| Attribute | Polyester (PET) | Nylon (PA) | Recycled PET |

|---|---|---|---|

| Hand Feel | Medium, stable | Softer, silky | Medium, stable |

| Mesh Gauge (aperture) | 1.5–3.0 mm typical | 0.8–2.0 mm typical | 1.5–3.0 mm typical |

| Denier/GSM | 50–120D / 80–140 GSM | 40–100D / 70–130 GSM | 50–120D / 80–140 GSM |

| Heat Tolerance | Good (dryer-safe low–medium) | Good (dryer-safe low–medium) | Good (dryer-safe low–medium) |

| Durability | High | High | High |

| Cost | $ | $$ | $–$$ |

| Sustainability | Standard | Standard | Better (recycled content) |

Bottom line: Pick nylon fine mesh for delicate items that snag easily. Choose polyester for broad use, higher structure, and value.

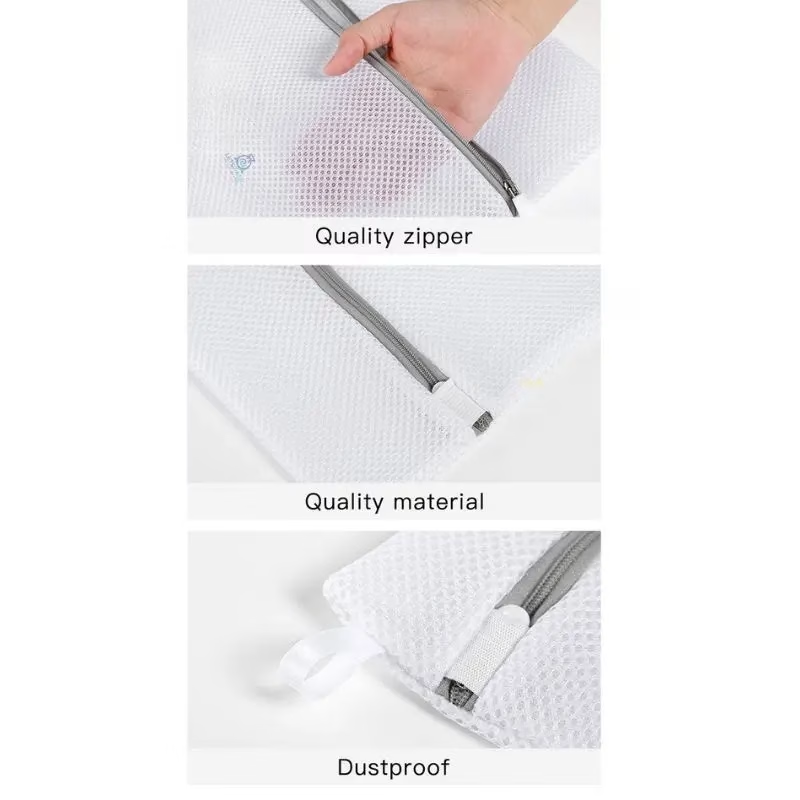

Closures & Construction: The Case for a Laundry Bag with Zipper

Closures are a big deal. Zippers keep items contained and stable in the drum.

What to look for:

Nylon coil zipper with auto-lock slider so it doesn’t creep open mid-cycle.

Zipper garage (cover) to hide the pull tab and prevent abrasion.

Bar-tacks at the zipper ends and corners to handle stress.

Binding (tape) over seams to reduce friction and improve durability.

Overlock stitching plus top-stitching for a clean, strong edge.

Drawstring vs. zipper? Drawstrings are fine for light, large items. But for mixed small garments, a laundry bag with zipper wins on containment and consistency.

Shapes & Set Planning for Retail and Facilities

Bags come in multiple shapes and set compositions, each with a job to do.

Shapes:

Rectangle/flat: Most common. Easy to load and fold.

Cylinder: Keeps bras and shoes shaped; often with a foam ring.

Cube/box: Great for bedding sets; holds form in large washers.

Gusseted flat: Extra depth helps for chunky knitwear.

Set planning:

Retail 3–6 piece sets: S/M/L bags + a bra cylinder. Color-coded zipper tabs for sorting.

Facility packs: Bulk M/L/XL single-size cartons for uniformity and easy replenishment.

Travel kits: Lightweight M and L with a pouch for compact packing.

Durability, Testing & Compliance

You want bags that survive repeated spins without fraying or popping open. Here’s what we validate at production:

Seam strength: Pull tests on side seams and zipper ends.

Slider life: Open/close cycles to confirm auto-lock holds.

Snag tests: Ensure mesh resists catching on hooks or Velcro.

Color fastness: Zipper tapes that don’t bleed.

REACH considerations: Materials and dyes screened to meet current requirements, with supporting documentation available on request.

Construction tips for longevity:

Select binding over raw overlock when bags will see 100+ cycles.

Add double bar-tacks at the zipper box for XL and jumbo sizes.

Pick medium mesh for better balance of protection and flow.

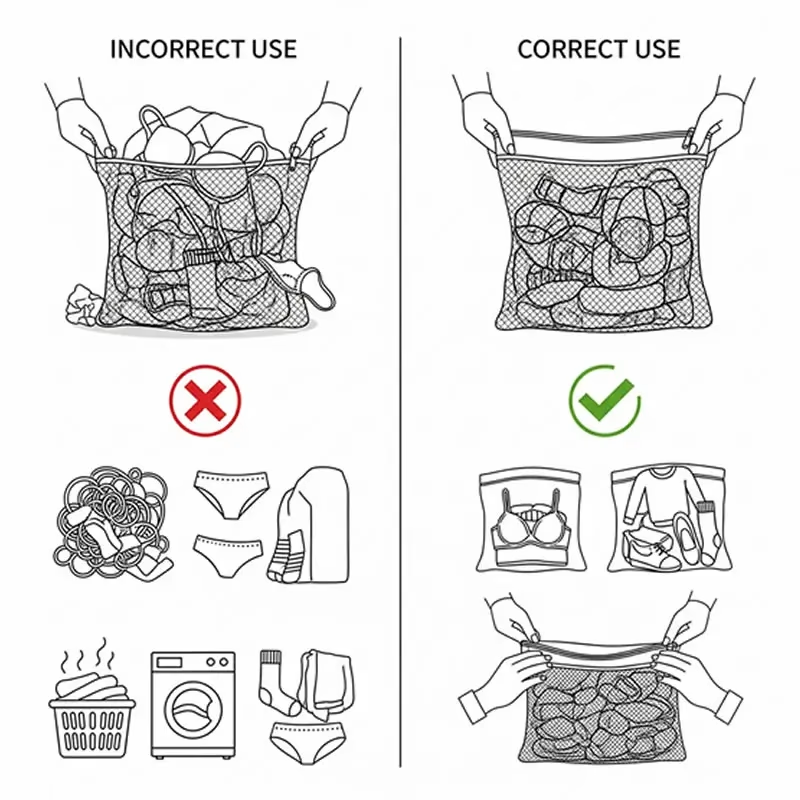

Care and Use Tips for Every Laundry Washer Bag

Treat the bag well, and it treats your garments well.

Zip, then tuck: Zip closed and place the slider in the garage.

Sort by weight: Don’t wash heavy jeans with lace bras in the same laundry washer bag.

Fill to 2/3: Leave room for water to do its job.

Use mild detergent: Strong bleaches can degrade mesh and zipper tape.

Dry low or line-dry: Heat ages elastic and tapes.

Rotate sets: Keep a few bags on hand so you’re not overusing one.

Procurement & OEM: From MOQ to Packaging

Planning a program for retail or facility use? Here’s a simple framework.

Specs that matter:

Material: PET or nylon; recycled options available.

Mesh gauge: Fine for delicates, medium for general, coarse for linens.

Zipper: Nylon coil, auto-lock, color-coded puller, zipper garage.

Seams: Overlock + binding; bar-tacks at stress points.

Sizes: Define a set (S/M/L + special shapes) or single-size bulk.

Branding: Woven label, heat-transfer logo, printed insert card.

Packaging: Polybag with insert, yiwu band, zipper pouch, or paper wrap—choose based on channel and sustainability goals.

Commercial notes (typical ranges):

MOQ: Commonly 1,000–3,000 sets for retail; 2,000–5,000 pieces per size for facility packs.

Lead time: Approx. 25–45 days after approval, depending on customization and season.

Testing: REACH-related documentation and colorfastness tests available.

Carton packs: Standard 50–100 pieces per carton; barcodes and carton labels provided.

Who we are

Established in 2014, we manufacture laundry mesh bags, washing bags, laundry baskets, storage boxes, and dirty clothes baskets. Our customers span Europe, North America, South America, Korea, and Japan. OEM orders are welcome, and custom designs are available. We use environment‑friendly raw materials and can support REACH and related test needs.

Sustainability and Responsible Materials

You can reduce impact without sacrificing performance.

Recycled PET: Uses post-consumer bottles. Similar strength and feel.

Zipper tapes & pullers: Recycled options available.

Paper-first packaging: Belly bands and insert cards from recycled paper.

Compact sets: Smaller pouches mean less freight volume.

Program tip: Specify recycled content percentage and request documentation to support marketing claims.

Common Pitfalls and How to Avoid Them

A few small mistakes cause most returns. Here’s how to dodge them.

No zipper garage: Slider scrapes fabrics; add a garage.

Too fine mesh for heavy items: Reduces water flow; pick medium or coarse.

Under-spec seams: Use binding and bar-tacks for XL and jumbo.

Overstuffing: Caps water flow; stick to 2/3 rule.

Mixed heavy & lace loads: Separate by weight and snag risk.

Real-World Use Cases & Set Ideas

Tailor bags to where they’ll live.

Hotels & spas: XL bags for towels; color-coded zipper tabs for departments.

Gyms & teams: L bags for kits; printed number tags for tracking.

Online retail: 3–6 piece sets with UPC, insert card, and care icons.

Residences: M and L bags for daily sorting; a cylinder for bras and shoes.

Care facilities: Name label zone and larger zipper pulls for ease of use.

Care Labels, Icons & Consumer Education

A small care panel on the bag or insert card goes a long way: wash temp, cycle type, dryer setting, and the “2/3 fill” rule. Clear icons reduce returns and customer service questions.

Maintenance & Replacement Planning

For heavy-use environments, budget for replacements every 12–18 months. Rotate sets to balance wear. Standardize sizes and color tabs to simplify reorders.

Spec Checklist: Copy-Paste for Your RFQ

Use this as your template:

Material: PET / Nylon / RPET (___% recycled)

Mesh gauge: Fine / Medium / Coarse (aperture ___ mm)

Color: White / Black / Custom (Pantone ___)

Sizes: S (20×30 cm), M (30×40 cm), L (40×50 cm), XL (50×60 cm), Jumbo (60×70 cm), Cylinder (dia. ___ × ___)

Closure: Nylon coil zipper, auto-lock slider, zipper garage (Y/N)

Seams: Overlock + binding, bar-tacks at corners and zipper ends

Branding: Woven label / Heat-transfer / Print

Packaging: Polybag w/ insert / Belly band / Zipper pouch / Paper wrap

Testing: REACH-related documentation, color fastness, seam pull test

Carton pack: ___ pcs per carton; UPC/EAN on packs; carton labels

Target lead time: ___ days after approval

Annual volume / release schedule: ___

Before You Go: Smarter Buys, Longer Wear

Mesh Laundry Bags protect garments, speed sorting, and lower claims. Choose the right size, match mesh to the job, and insist on a quality zipper and solid seams. For retail programs or facility rollouts, lock in specs, packaging, and tests early. You’ll save time, reduce waste, and keep customers happy.

We’ve produced mesh bags at scale since 2014, serving Europe, North America, South America, Korea, and Japan. OEM orders are welcome, and customized designs are available. Our materials are environment-friendly and can pass REACH and related tests.

Ready to source? Explore our current laundry mesh bag lineup and send your RFQ. We’ll help you tailor sizes, materials, and packaging for your channel

FAQs

Q1: What mesh gauge should we choose for a mixed-use retail set?

For a 3–6 piece set, pair fine mesh for delicates (S/M) with medium mesh for general apparel (M/L) and a structured cylinder for bras or shoes. This covers 90% of household needs without confusing shoppers.

Q2: Can you support REACH and similar compliance documentation?

Yes. We source environment-friendly materials and can support REACH-related documentation along with colorfastness and seam-strength testing. Please specify the test list during RFQ so we align timelines.

Q3: What is a sensible MOQ and lead time for private-label sets?

Typical MOQ is 1,000–3,000 sets for retail programs. Lead time is often 25–45 days after approval, depending on customization and season. We’ll confirm the schedule with your packaging and test requirements.

Q4: Which closure should we pick for facilities that wash large volumes?

Choose a laundry bag with zipper featuring a nylon coil and an auto-lock slider, plus a zipper garage. It keeps loads contained and reduces rewash. Add bar-tacks at stress points for XL and jumbo sizes.

Q5: Do you offer recycled materials and eco packaging?

Yes. Recycled PET fabric, recycled zipper tapes, and paper-first packaging are available. Specify your target recycled content and we’ll quote options.