Ever watched a delicate garment get ruined because it tangled with heavier items in the wash? You’re not alone. Thousands of laundry operations face damaged items, lost productivity, and customer complaints daily. The solution sits right in front of you—an extra large mesh laundry bag that protects delicates while maximizing washing capacity. But here’s where it gets tricky: not all mesh bags deliver the same performance.

Whether you manage a hotel laundry facility, run a commercial cleaning service, or oversee institutional operations, choosing the right laundry bag impacts your bottom line. The wrong choice means frequent replacements, damaged items, and wasted time. Let’s dive into what separates professional-grade mesh bags from the rest.

Understanding Extra Large Mesh Laundry Bags: More Than Just Size

When we talk about extra large mesh laundry bags, we’re discussing bags that typically measure 24″ x 36″ or larger. These aren’t your standard household bags. They’re engineered for heavy-duty use, designed to handle 15-20 pounds of laundry while maintaining their structure wash after wash.

The mesh construction serves multiple purposes. First, it allows water and detergent to flow freely through the fabric, ensuring thorough cleaning. Second, it prevents items from tangling with other garments or getting caught in washing machine agitators. Third, the visibility through the mesh helps sorting and identification without opening each bag.

Professional operations need bags that withstand hundreds of wash cycles. Standard polyester mesh bags might seem economical initially, but they often tear at stress points within weeks. Premium options use reinforced polyester or nylon mesh with double-stitched seams. These last months or even years under heavy use.

Key Components of Professional-Grade Mesh Bags

The zipper often determines a bag’s lifespan. Cheap plastic zippers break quickly under the strain of heavy loads. Quality bags feature rust-resistant metal zippers or heavy-duty nylon zippers with protective covers. These covers prevent the zipper from snagging delicate items during washing.

Mesh density matters too. Finer mesh (around 3mm holes) protects delicates better but may restrict water flow. Coarser mesh (5-7mm) allows better circulation but offers less protection. The sweet spot for most commercial applications sits around 4-5mm—enough protection without compromising cleaning efficiency.

The drawstring versus zipper debate continues among professionals. Drawstring bags offer quick loading and unloading, making them ideal for high-volume operations. However, extra large laundry bags with zipper closures provide better security, especially for items with straps or hooks that might escape during agitation.

Comparing Size Options: Finding Your Perfect Fit

Not all “extra large” bags measure the same. Manufacturers use different sizing standards, creating confusion for buyers. Let’s break down the common sizes and their typical applications:

Standard Size Classifications

X large laundry bags typically measure 20″ x 24″ to 24″ x 30″. They handle about 10-15 pounds of laundry comfortably. These work well for smaller commercial operations or segregating specific item types within larger loads.

True extra large mesh bags start at 24″ x 36″ and can reach 30″ x 40″ or larger. These accommodate 15-25 pounds, making them ideal for bulk processing. Hotels use them for guest linens, while medical facilities rely on them for scrubs and patient gowns.

Some manufacturers offer jumbo or industrial sizes reaching 36″ x 45″. These giants handle up to 35 pounds but require careful handling to avoid strain on washing machine components. They’re perfect for lightweight but bulky items like comforters or sleeping bags.

Size Selection Table

| Bag Size | Dimensions | Capacity | Best Use Cases | Load Examples |

|---|---|---|---|---|

| Large | 18″ x 24″ | 8-10 lbs | Small loads, delicates | 6-8 shirts, undergarments |

| X-Large | 24″ x 30″ | 10-15 lbs | Medium commercial loads | 10-12 towels, bed sheets |

| Extra Large | 24″ x 36″ | 15-20 lbs | Standard commercial use | 15-20 uniforms, linens |

| Jumbo | 30″ x 40″ | 20-30 lbs | Bulk processing | Comforters, multiple sheet sets |

| Industrial | 36″ x 45″ | 30-35 lbs | High-volume operations | Bulk linens, sleeping bags |

The right size depends on your specific needs. Oversized bags for small loads waste water and energy. Undersized bags require more cycles, increasing labor costs. Consider your typical load composition when selecting sizes.

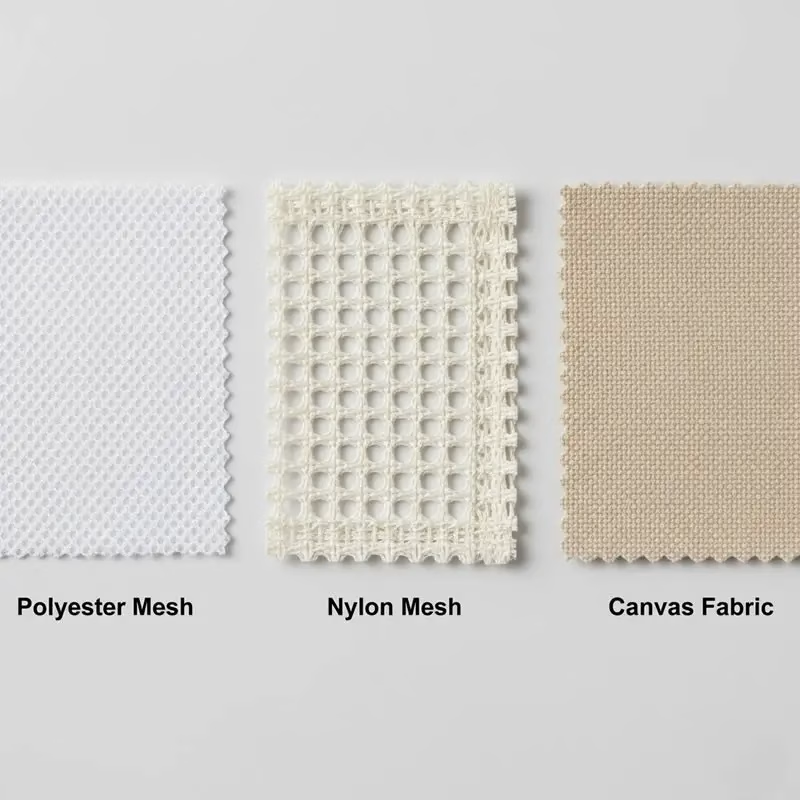

Material Matters: Polyester vs. Nylon vs. Canvas Options

The material choice significantly impacts durability, performance, and cost. While mesh dominates the commercial market, understanding all options helps make informed decisions.

Polyester Mesh: The Industry Standard

Polyester mesh represents about 70% of commercial laundry bags sold today. It resists shrinking, maintains color through bleaching, and costs less than alternatives. Modern polyester blends incorporate UV resistance and antimicrobial treatments, extending useful life.

Quality varies widely among polyester options. Budget bags use single-layer mesh that tears easily. Professional-grade bags feature double-layer construction or reinforced stress points. Look for bags with at least 210 denier polyester—thicker threads that resist tearing.

Heat resistance becomes crucial for commercial dryers. Standard polyester handles temperatures up to 140°F comfortably. Higher grades withstand 160°F or more. This matters when processing items requiring high-heat sanitization, like healthcare linens.

Nylon Mesh: Premium Performance

Nylon mesh costs more but delivers superior strength. It stretches without tearing, making it ideal for variable load sizes. The material also resists abrasion better than polyester, important when washing items with zippers or buttons.

The main drawback? Nylon absorbs water, increasing drying time. It also yellows over time, especially with chlorine bleach exposure. However, for operations prioritizing durability over appearance, nylon remains the top choice.

Canvas Options: Specialized Applications

Extra large canvas laundry bags serve different purposes than mesh alternatives. They completely contain items, preventing any chance of escape. This makes them perfect for heavily soiled items or those requiring isolation during transport.

Canvas bags excel at protecting extremely delicate items. Museums and restoration services use them for vintage textiles. The solid construction blocks direct water jets that might damage fragile fabrics. However, limited water flow means longer wash cycles and potential cleaning issues.

Heavy-duty canvas withstands rough handling during transport and storage. Many operations use canvas bags for dirty laundry collection, then transfer items to mesh bags for washing. This two-bag system maximizes efficiency while protecting equipment.

Price Analysis: Understanding Cost vs. Value

Price varies dramatically across the market. Budget bags start around $3-5 each, while premium options reach $15-25. Understanding what drives these differences helps justify investment decisions to stakeholders.

Initial Cost Factors

Material quality accounts for about 40% of price variation. Premium polyester costs three times more than basic grades. Add antimicrobial treatments or UV resistance, and prices climb further. Nylon mesh commands a 30-50% premium over comparable polyester.

Construction methods significantly impact cost. Machine-stitched bags cost less but may unravel under stress. Serged seams cost more but last longer. Heat-welded seams, found on premium bags, eliminate thread failure entirely but require specialized equipment, driving prices higher.

Closure mechanisms affect pricing too. Basic drawstrings add minimal cost. Quality zippers with protective covers can add $2-4 per bag. Self-repairing zippers, which automatically realign teeth if forced open, add even more but virtually eliminate zipper failures.

Total Cost of Ownership Table

| Bag Type | Initial Cost | Average Lifespan | Cost per Month | Replacement Frequency |

|---|---|---|---|---|

| Budget Polyester | $3-5 | 2-3 months | $1.50-2.50 | 4-6 times/year |

| Standard Polyester | $6-9 | 6-9 months | $0.75-1.50 | 1-2 times/year |

| Premium Polyester | $10-15 | 12-18 months | $0.65-1.25 | Every 1-1.5 years |

| Nylon Mesh | $12-18 | 18-24 months | $0.50-1.00 | Every 1.5-2 years |

| Reinforced Canvas | $15-25 | 24-36 months | $0.45-1.00 | Every 2-3 years |

These calculations assume daily commercial use. Light-duty applications see proportionally longer lifespans. Factor in labor costs for replacing failed bags—premium options often pay for themselves through reduced maintenance time.

Hidden Costs of Cheap Bags

Damaged items represent the biggest hidden cost. One ruined silk blouse or cashmere sweater exceeds the savings from buying cheap bags. Insurance claims and customer compensation quickly erode any perceived savings.

Labor inefficiency adds up too. Cheap bags require careful handling to avoid tears. Workers spend extra time checking for damage, transferring items between bags, and dealing with spills from failed closures. Premium bags eliminate these time wasters.

Equipment damage poses another risk. Torn bags release items into washing machines, potentially damaging pumps or drums. One service call typically costs more than upgrading an entire bag inventory. Prevention beats repair every time.

Durability Testing: What Really Matters

Manufacturers make bold durability claims, but real-world performance often differs. Understanding testing standards helps evaluate these claims objectively.

Industry Testing Standards

The Textile Research Institute developed standardized tests for commercial laundry bags. These include tensile strength (how much weight before tearing), abrasion resistance (cycles before showing wear), and closure integrity (operations before failure). Reputable manufacturers publish these test results.

Tensile strength testing pulls fabric until failure. Professional bags should withstand at least 50 pounds of force—double the typical load weight. Premium bags often exceed 75 pounds, providing substantial safety margins. This extra strength prevents catastrophic failures that spill contents mid-cycle.

Abrasion testing simulates repeated washing. Bags undergo 500-1000 cycles with weighted rubber balls mimicking laundry movement. Quality bags show minimal wear after 500 cycles. Premium options survive 1000+ cycles with only minor pilling or thinning.

Real-World Performance Factors

Laboratory tests don’t capture everything. Chemical exposure affects longevity significantly. Chlorine bleach weakens polyester over time. Industrial detergents with high pH levels accelerate degradation. Fabric softeners can clog mesh openings, reducing cleaning effectiveness.

Temperature cycling stresses materials differently than constant heat. Extra large mesh laundry bags for washing machine use must withstand repeated hot water exposure followed by high-heat drying. This thermal cycling causes some materials to become brittle over time.

User handling impacts durability more than any other factor. Overloading bags strains seams and zippers. Dragging bags across floors causes abrasion. Training staff on proper handling extends bag life significantly—sometimes doubling usable lifespan.

Durability Comparison by Use Case

| Application | Required Durability | Recommended Material | Expected Lifespan |

|---|---|---|---|

| Hotel Linens | High | Premium polyester | 12-18 months |

| Medical Scrubs | Very High | Nylon or reinforced polyester | 18-24 months |

| Delicate Garments | Medium | Fine mesh polyester | 9-12 months |

| Industrial Uniforms | Extreme | Heavy canvas or nylon | 24-36 months |

| Athletic Wear | High | Antimicrobial polyester | 12-15 months |

Consider your specific use case when evaluating durability needs. Overbuying wastes money, but underbuying causes operational headaches. Match bag specifications to actual requirements for optimal value.

Specialty Features Worth Considering

Modern extra large laundry bags offer features beyond basic containment. These additions can streamline operations and reduce costs when properly utilized.

Color Coding Systems

Color-coded bags eliminate sorting confusion. Hotels assign specific colors to room categories. Medical facilities use colors to separate contamination levels. This visual system reduces errors and speeds processing.

Some manufacturers offer permanent color options through dyed fabric. Others use colored binding or zipper tape for identification. Removable color tags provide flexibility but may get lost. Choose the system matching your operational needs.

The psychology of color matters too. Red bags signal caution for heavily soiled items. Blue often indicates standard processing. Green might designate eco-friendly or hypoallergenic handling. Consistent color use across facilities improves compliance and reduces training time.

Identification and Tracking

Built-in ID windows protect paper or plastic cards while maintaining visibility. These prove invaluable for tracking customer orders or departmental items. Some windows feature waterproof seals, protecting barcodes or RFID tags from moisture damage.

RFID-compatible bags represent the cutting edge. Embedded tags survive hundreds of wash cycles, enabling automatic sorting and tracking. While adding $3-5 per bag initially, RFID systems can reduce labor costs by 20-30% in high-volume operations.

QR code patches offer a middle ground. Heat-sealed patches withstand commercial washing while enabling smartphone scanning. This technology bridges manual and automated systems without requiring expensive infrastructure changes.

Antimicrobial and Odor Control

Antimicrobial treatments inhibit bacterial and fungal growth between washes. This proves especially valuable for bags storing damp items before washing. Silver ion technology leads this category, providing long-lasting protection without chemical odors.

Odor-control fabrics incorporate activated carbon or zeolite particles. These materials absorb odor molecules, preventing smell transfer between items. Sports facilities and gym laundries find these features particularly valuable for managing athletic wear.

Some manufacturers now offer biodegradable antimicrobial treatments using plant-based compounds. These appeal to environmentally conscious operations while maintaining effectiveness. The treatments typically last 50-100 washes before requiring reapplication

Installation and Workflow Integration

Successfully integrating extra large mesh bags into existing operations requires planning. The best bags fail without proper implementation strategies.

Sorting Station Setup

Dedicate specific areas for bag loading. Install hooks or racks at comfortable working heights—typically 36-42 inches. This reduces back strain while improving efficiency. Position scales nearby for weight verification, preventing overloading.

Create clear pathways between sorting and washing areas. Bags dragged across floors wear prematurely. Wheeled carts or overhead rail systems protect bags while speeding transport. Calculate distances and traffic patterns when designing layouts.

Label everything clearly. Use multilingual signs if necessary. Visual guides showing proper loading techniques reduce training time and improve compliance. Post weight limits prominently. Small investments in signage prevent expensive mistakes.

Washing Machine Compatibility

Verify machine capacity before purchasing bags. A 60-pound capacity washer handles two 25-pound bags comfortably but struggles with three. Overloading reduces cleaning effectiveness and strains equipment. Plan bag sizes around actual machine capabilities.

Front-loading machines work best with mesh bags. The tumbling action provides gentle but thorough cleaning. Top-loaders with agitators can snag bags, causing tears. If using top-loaders, choose bags with reinforced construction and protective zipper covers.

Program appropriate cycles for bagged items. Reduce spin speeds slightly to prevent stress on seams. Add 2-3 minutes to wash times, compensating for restricted water flow. These minor adjustments significantly extend bag life while maintaining cleaning quality.

Quality Control Measures

Implement inspection protocols for bags and contents. Check bags for damage before each use. Small tears become major failures quickly. Establish clear criteria for bag retirement—typically when repairs exceed 10% of surface area.

Train staff to recognize overloading signs. Straining zippers, stretched mesh, and difficulty closing indicate excessive weight. Provide quick reference cards showing maximum items per bag type. Regular training refreshers maintain standards.

Document bag performance metrics. Track failure rates, average lifespan, and damage patterns. This data justifies equipment investments and identifies operational improvements. Modern laundry management software often includes bag tracking modules.

Maintenance Best Practices

Proper maintenance doubles or triples bag lifespan. These practices require minimal time but deliver substantial returns.

Daily Care Routines

Empty bags completely after each use. Retained items cause odors and potentially damage fabric. Turn bags inside out weekly, removing accumulated lint and debris. This simple step maintains mesh permeability and cleaning effectiveness.

Air-dry bags when possible. While most withstand commercial dryers, air drying extends lifespan by reducing thermal stress. If machine drying, use low heat settings. High heat weakens synthetic fibers and can damage zippers.

Rotate bag inventory regularly. Marking bags with dates or codes enables tracking. Using bags in sequence ensures even wear distribution. This prevents premature failure of frequently used bags while others sit idle.

Cleaning and Sanitization

Wash empty bags weekly using hot water and standard detergent. This removes accumulated soil and maintains appearance. Add chlorine bleach monthly for sanitization, following manufacturer dilution recommendations. Some facilities dedicate specific wash cycles to bag maintenance.

Address stains promptly. Blood, ink, and other substances become permanent if left untreated. Pre-treat stains with appropriate removers before washing. Enzyme cleaners work well for protein-based stains common in healthcare settings.

Deep clean quarterly using specialized products. Degreasers remove built-up fabric softener residue. Descalers eliminate mineral deposits from hard water. These treatments restore original performance and appearance.

Repair vs. Replace Decisions

Minor repairs extend bag life economically. Small tears under 2 inches can be patched using iron-on mesh patches. Loose seams benefit from reinforcement stitching. Keep basic repair supplies readily available for quick fixes.

Know when replacement makes sense. Repairs exceeding 20% of replacement cost rarely prove economical. Multiple repairs on the same bag indicate fundamental failure. Safety concerns always warrant immediate replacement.

Consider professional repair services for expensive bags. Some manufacturers offer refurbishment programs, replacing zippers and reinforcing seams for 30-50% of new bag costs. This option works well for premium bags with mostly intact mesh.

Common Mistakes to Avoid

Even experienced operations make mistakes that shorten bag life and increase costs. Learning from others’ errors prevents repeating them.

Overloading Issues

The most common mistake involves exceeding weight limits. Bags might close despite overloading, but stress accumulates with each cycle. Seams gradually weaken until catastrophic failure occurs. Train staff that “fitting” doesn’t equal “appropriate.”

Volume matters as much as weight. Stuffing bags to capacity prevents proper water circulation. Items emerge poorly cleaned, requiring rewashing. This doubles processing time and costs while frustrating customers. Maintain 20-30% free space for optimal results.

Mixed load types cause problems too. Heavy items like jeans shouldn’t share bags with delicates. The weight differential causes excessive movement, potentially damaging lighter items. Separate loads by weight and fabric type for best results.

Temperature Mismanagement

Exceeding temperature ratings destroys bags quickly. Polyester rated for 140°F might survive occasional 160°F exposure but fails rapidly with repeated high-heat cycles. Know your bags’ limits and program machines accordingly.

Rapid temperature changes prove equally damaging. Moving bags directly from hot dryers to cold storage areas causes thermal shock. This makes materials brittle over time. Allow cooling periods when possible, especially for heavy-duty canvas bags.

Chemical interactions with heat accelerate damage. Chlorine bleach becomes more aggressive at higher temperatures. Reduce bleach concentration when using hot water, or switch to oxygen-based alternatives for high-temperature washing.

Storage and Handling Errors

Storing damp bags promotes mold and mildew growth. Always ensure complete drying before storage. Persistent moisture also weakens fabric fibers and corrodes metal zippers. Dedicate adequate drying space and time in operational planning.

Improper stacking damages bags unnecessarily. Heavy items placed on top of bagged laundry compress mesh and stress seams. Use shelving systems that support bags properly without excessive pressure. Never stack more than three bags high.

Dragging bags across rough surfaces causes premature wear. Concrete floors prove particularly abrasive. Provide wheeled carts or install smooth pathways in high-traffic areas. The infrastructure investment pays dividends through extended bag life.

Making the Right Choice for Your Operation

Selecting the ideal extra large mesh laundry bag requires balancing multiple factors. No single solution fits every operation perfectly.

Assessing Your Needs

Start by auditing current operations. Document daily laundry volumes, common item types, and processing frequencies. This baseline data drives informed decisions. Many operations discover they need multiple bag types rather than one universal solution.

Consider growth projections. Buying for current needs might seem economical, but upgrading systems proves disruptive and expensive. Factor in 20-30% capacity growth when sizing purchases. Quality bags last long enough to accommodate reasonable expansion.

Evaluate staff capabilities honestly. Complex systems with multiple bag types and sorting requirements need trained, stable workforces. High-turnover operations benefit from simpler solutions, even if slightly less efficient. Match complexity to organizational reality.

Vendor Evaluation Criteria

Look beyond price when selecting suppliers. Established manufacturers like those with six years of experience, serving markets across Europe, North America, and Asia, bring invaluable expertise. They understand commercial requirements and offer appropriate solutions.

Verify environmental credentials. REACH compliance and similar certifications indicate responsible manufacturing. These bags won’t release harmful chemicals during washing or disposal. Environmental responsibility increasingly influences purchasing decisions and brand reputation.

Request samples before bulk purchases. Test bags under actual operating conditions for at least two weeks. This reveals potential issues invisible in specifications. Compare multiple options simultaneously for objective evaluation.

Implementation Timeline

| Phase | Duration | Activities | Success Metrics |

|---|---|---|---|

| Planning | 2 weeks | Needs assessment, vendor selection | Requirements documented |

| Testing | 2-4 weeks | Sample evaluation, staff training | Performance data collected |

| Rollout | 1-2 weeks | Initial deployment, monitoring | Adoption rate >80% |

| Optimization | Ongoing | Process refinement, feedback incorporation | Efficiency improvements |

| Review | Quarterly | Performance analysis, adjustments | ROI targets met |

Phase implementation gradually rather than wholesale replacement. This approach minimizes disruption while allowing process refinement. Start with one department or facility before expanding successful systems.

Maximizing Your Investment

Choosing the right extra large mesh laundry bag impacts more than just laundry operations. It affects customer satisfaction, employee efficiency, and ultimately, profitability. The initial investment in quality bags pays dividends through reduced replacement costs, fewer damaged items, and improved operational flow.

Remember that the cheapest option rarely provides the best value. Professional-grade bags from established manufacturers, particularly those with proven track records in global markets, deliver consistent performance and reliability. When sourcing bags, prioritize vendors who understand commercial laundry challenges and offer customized solutions.

Start your upgrade today. Whether you need extra large mesh laundry bags for washing machine use, heavy-duty canvas options, or specialized antimicrobial treatments, the right supplier makes all the difference.

Ready to Transform Your Laundry Operations?

As an established manufacturer since 2014, we’ve supplied premium mesh laundry bags to operations across Europe, North America, South America, Korea, and Japan. Our complete product range includes everything from small specialty bags to comprehensive laundry bag sets designed for commercial use.

Looking for specific solutions? Explore our premium polyester mesh bags with reinforced zippers or large capacity options engineered for heavy-duty applications. We even offer specialized items like mesh bra laundry bags for delicate garments.

Get Your Custom Quote Today – Our OEM services and customization options mean you get exactly what your operation needs. With REACH-compliant, environmentally friendly materials and six years of manufacturing expertise, we’re your trusted partner for commercial laundry solutions. Contact us now to discuss your requirements and receive samples for testing.

Frequently Asked Questions

Q: What’s the ideal weight capacity for extra large mesh laundry bags?

A: For commercial use, 15–20 lbs is ideal. Hotels and hospitals often cap at 18 lbs for longer bag life. Avoid overloading to prevent wear.

Q: How can we calculate ROI on premium mesh bags?

A: Compare total costs over 24 months. Premium bags usually pay off in 6–8 months by reducing replacements and saving labor time.

Q: Should mesh density vary by fabric type?

A: Yes. Fine mesh for delicates, standard for linens, coarse for heavy fabrics. Color-coding helps cut fabric damage by up to 40%.

Q: What certifications should suppliers provide?

A: Look for REACH, ISO 9001, and HLAC standards. Ensure antimicrobial treatments have EPA registration and strength test reports.

Q: How to prevent cross-contamination between departments?

A: Use color-coded bags, sanitize at 150°F with 150ppm bleach, and consider RFID tracking for strict bag assignment control.