If you manage uniforms, guest linens, or production samples, you’ve likely wrestled with flimsy sacks and mismatched sizes. Orders stall. Items go missing. Costs creep. That stops when you switch to custom laundry bags built for your workflow. This guide gives you a clear path—from defining specs to signing off on samples—so your next bulk order arrives on time, within budget, and ready for years of use. You’ll see how to choose materials, sizes, printing, closures, and packaging, along with real-world tips for quality checks and logistics. By the end, you’ll know exactly how to brief a manufacturer and place a confident order for custom laundry bags that fit your team, your brand, and your budget.

Why Custom Laundry Bags Solve Everyday Pain Points

Laundry operations are full of small leaks that add up. Labels peel. Zippers snag. Drawstrings snap. Printed logos fade. When bag specs don’t match the job, staff work harder and costs rise. Well-designed custom laundry bags fix that. They protect garments, simplify sorting, and carry brand identity across facilities.

Common pain points and simple fixes:

- Mixed loads & lost items. Use color-coded custom mesh laundry bags and printed zones to group garments by size, wearer, or department.

- Damage in wash cycles. Choose fine or coarse mesh depending on fabric. Add reinforced seams and rust-proof hardware.

- Slow sorting. Print scannable codes, room numbers, or department names on each personalized laundry bag.

- Logo fading. Pick heat-resistant inks or embroidery; request wash-test proof in your pre-production sample.

- Weak closures. Spec bar-tacked drawstring channels or auto-lock zippers; match closure to load weight and cycle type.

Our company background: Established in 2014, we manufacture laundry mesh bags, washing bags, laundry baskets, storage boxes, and dirty clothes baskets. We serve customers across Europe, North America, South America, Korea, and Japan. OEM orders are welcome and customized designs are available. Our raw materials are environment-friendly and can pass REACH and related tests.

The Fastest Way to Define Your Custom Laundry Bag Requirements

Before you contact suppliers, gather five essentials. Having these details ready turns a fuzzy request into a production-ready brief for custom laundry bags.

1) Use Case and Capacity

Write a one-line goal, like: “Daily collection and machine-wash of spa robes, 6–8 kg per load, low-heat dry.”

Capacity points to size, seam type, and closure strength. If your use case includes delicate items, custom mesh laundry bags with fine mesh and padded seams protect fibers while allowing water flow.

2) Dimensions and Shape

Match bag size to your washer drum and cart footprint. Common shapes:

- Flat sack: simple, efficient, great for bulk linens.

- Gusseted bag: stands with structure, good for uniforms and folded pieces.

- Cylinder/duffel: better for transport; use double handles.

Tip: When in doubt, request a fabric mockup or size card. A 1–2 cm tolerance is standard on textiles.

3) Material and Mesh

Pick material for handling, cycle temperature, and print method. For custom laundry bags, the most common:

- Polyester fine mesh (e.g., 70–100 gsm): gentle on delicates, smooth hand feel, supports heat transfer print.

- Polyester coarse mesh (e.g., 120–200 gsm): heavy-duty, fast drain, durable under load.

- Oxford or canvas: transport and storage; not always for in-machine use.

- Recycled yarn options: ask for GRS or similar if sustainability matters.

4) Closure and Hardware

Choose drawstring (with cord lock), zipper (auto-lock), or buckle. Specify bar-tack reinforcement at stress points and rust-proof components.

5) Branding and Identification

Decide on logo placement, size, and method (screen, heat transfer, embroidery). Add functional markings: size letters, room numbers, staff IDs, or QR codes. For personalized mesh laundry bag orders, assign a unique code per user to avoid mix-ups.

Featured Products to Reference During Spec Building

- Laundry bag set — see our Laundry Bag Set for multi-size options.

- Thickened coarse mesh with customized logo — ideal for heavy linens: Set of 5 Coarse Mesh.

- Colorful fine mesh — color coding for departments: Fine Mesh Wholesaler.

- Flower print mesh set — retail-friendly patterns: Print Mesh Set.

- Bra laundry bag — structured protection: Mesh Bra Bag (Black Zipper).

- Embroidered logo — premium branding: White Mesh with Embroidery.

You can also browse the full range here: our products.

Understanding Different Types of Custom Mesh Laundry Bags

Not all laundry bags are created equal. The type you choose depends on what goes inside them and how they’ll be used.

Fine Mesh vs. Coarse Mesh

Fine mesh bags work best for delicate items. Lingerie, hosiery, and lightweight garments need the protection of smaller holes. The mesh prevents snags while allowing water and detergent to flow through. These bags typically handle everyday washing but aren’t built for industrial-level abuse.

Coarse mesh bags handle heavier loads. They’re the workhorses of commercial laundry operations. Sports uniforms, work clothes, and heavier fabrics do better with larger mesh openings. Water circulates more freely, which means better cleaning. The thicker construction stands up to repeated commercial washing cycles.

Check out our range of laundry bag options to see the different mesh types available.

Drawstring vs. Zipper Closure

Drawstring bags offer simplicity. They’re faster to use and have fewer parts that can break. Staff in hotels or hospitals appreciate the speed when processing hundreds of bags daily. The trade-off is that items can occasionally slip out if the bag isn’t closed properly.

Zipper closures provide better security. Nothing falls out during transport or washing. Retail customers prefer them for that reason. The downside is that zippers can break, especially low-quality ones. When ordering custom laundry bags wholesale, ask about zipper durability testing.

Single Bags vs. Sets

Individual bags work for specific applications. A mesh bra laundry bag targets one need perfectly. But many bulk buyers prefer laundry bag sets because they offer flexibility. A set might include different sizes for different garment types.

Material, Mesh, and Printing: Choosing the Right Build for Custom Laundry Bags

Not all fabrics behave the same in spin cycles, chlorine, or heat. Choose materials that match your cleaning method and volume.

Material Options at a Glance

Polyester Mesh: Durable, quick-drying, stable under repeat wash. Great for custom mesh laundry bags.

Nylon Mesh: Strong but can yellow in harsh chemicals; test if you use bleach.

Recycled Polyester Mesh: Similar performance with sustainability benefits; ask for documentation.

Oxford/Canvas: For transport, carts, and storage; sometimes lined for dust control.

Printing and Branding

- Screen printing: Crisp, cost-effective for 1–3 colors; durable when cured correctly.

- Heat transfer: Vivid detail, good for complex logos; verify wash temp limits.

- Embroidery: Premium look; note that dense fills can stiffen mesh.

- Woven/printed label: Clean solution for IDs and size markers.

Pro tip: Ask for a wash-test report with your pre-production sample (PPS). Request images after 10, 25, and 50 cycles.

Comparison Table: Mesh Types vs. Use Cases

| Mesh type | Typical gsm | Best for | Wash speed | Print compatibility | Notes |

|---|---|---|---|---|---|

| Fine polyester mesh | 70–100 | Delicates, lingerie, knitwear | Medium | Heat transfer, small embroidery | Gentle on fabrics; lower abrasion |

| Coarse polyester mesh | 120–200 | Towels, uniforms, heavy linens | Fast | Screen print, embroidery | High airflow; strong seams required |

| Nylon mesh | 80–150 | Mixed loads, light industrial | Medium | Screen print | Test for bleach; may yellow |

| Oxford fabric | 150–300 | Transport, storage, carts | N/A | Screen/heat transfer | Not always for machine wash |

Key Specifications to Consider When Ordering Custom Laundry Bags

Getting specifications right saves money and prevents headaches. Here’s what actually matters when you’re placing a bulk order.

Size and Capacity

Measure what you’re putting inside. Don’t guess. A bag that’s too small frustrates users. One that’s too large wastes material and shipping space.

Common sizes include:

- Small (30×40 cm) – delicates, socks, undergarments

- Medium (40×50 cm) – everyday clothing, gym clothes

- Large (50×60 cm) – bedding, bulky items

- Extra large (60×70 cm) – comforters, multiple uniforms

Calculate volume, not just dimensions. A bag might be technically large enough but have a shape that doesn’t work for your items.

Material Specifications

Polyester dominates the market because it’s durable and affordable. But not all polyester is identical.

Denier count matters. Higher denier means thicker thread. A 50D mesh bag feels flimsy. A 100D bag offers better durability. For commercial applications, look at 150D or higher.

Material treatment affects performance. UV resistance prevents sun damage if bags hang outside. Anti-bacterial treatment reduces odor, which matters for gym bags. Water-resistant coatings can be added for specific applications.

Environmental considerations are increasingly important. If you need bags that pass REACH compliance or other environmental tests, specify this upfront. Our materials are environment-friendly and meet these standards, which matters for European and North American markets.

Color and Print Options

Color choices aren’t just aesthetic. They serve practical purposes.

Color-coding helps with sorting. Hotels might use blue bags for sheets and white bags for towels. Schools might assign different colors to different teams. The system only works if the colors stay vibrant after repeated washing.

Print methods affect durability. Screen printing is economical for simple logos but can crack over time. Embroidery lasts longer but costs more per unit. Heat transfer works well for detailed designs. For a premium look, consider an embroidered logo option.

Comparison Table: Material Options

| Material Type | Durability Rating | Best Use Case | Price Point | Environmental Certification |

|---|---|---|---|---|

| Standard Polyester Mesh | Good | Retail, Light Commercial | Budget | Basic |

| Thickened Polyester | Excellent | Heavy Commercial, Industrial | Mid-Range | REACH Compliant |

| Fine Mesh Polyester | Fair | Delicates, Retail | Budget | REACH Compliant |

| Coarse Mesh Polyester | Excellent | Athletic, Hospitality | Mid-Range | REACH Compliant |

How to Find the Right Manufacturer for Custom Laundry Bags Wholesale

Finding a manufacturer is easy. Finding the right manufacturer takes more effort.

Experience and Specialization

How long has the manufacturer been making laundry bags specifically? Generic textile factories can produce them, but specialists understand the nuances. They know which mesh density works for what application. They’ve solved problems you haven’t encountered yet.

We’ve been manufacturing laundry mesh bags since 2014. That’s not ancient history, but it’s enough time to work through quality issues and refine production processes. Our customer base spans Europe, North America, South America, Korea, and Japan. Different markets have different expectations, and experience with diverse clients means we understand what “quality” means to you.

Manufacturing Capabilities

Ask about production capacity. Can they handle your order volume? A factory that’s perfect for 5,000 units might struggle with 50,000. Or they might have a high minimum order quantity that doesn’t fit your needs.

Check their customization options. Some manufacturers offer limited choices: pick from five colors and add a logo. Others can develop products from scratch. If you need a customized logo design or unique size, make sure they have the flexibility.

OEM capabilities matter for proprietary designs. If you’re creating something unique for your brand, you need a partner who welcomes OEM orders rather than one who treats customization as a burden.

Quality Certifications

Certifications aren’t just paperwork. They indicate process discipline.

REACH compliance matters for European markets. It means the product doesn’t contain harmful chemicals. California Prop 65 is similar for the U.S. market. If your bags will be used by children or in sensitive environments, these certifications aren’t optional.

Ask for test reports. A manufacturer who balks at sharing documentation is hiding something. We provide full testing documentation because our environment-friendly materials pass these tests consistently.

Communication and Responsiveness

How quickly do they respond to inquiries? What happens when you have a question at 10 PM your time? Do they have English-speaking staff who understand your requirements?

Time zone differences are real, but they shouldn’t mean waiting 24 hours for a simple answer. Look for manufacturers with systems in place to handle international communication efficiently.

Comparison Table: Manufacturer Selection Criteria

| Factor | What to Look For | Red Flags | Questions to Ask |

|---|---|---|---|

| Experience | 5+ years in laundry bags | Less than 2 years, no samples | “How many similar projects have you completed?” |

| Capacity | Can exceed your volume needs | Your order maxes out their capacity | “What’s your monthly production capacity?” |

| Customization | Multiple design and material options | Limited to standard options only | “Can you accommodate custom specifications?” |

| Quality Control | Clear testing procedures, certifications | Vague quality promises | “What certifications do your products have?” |

| Communication | Response within 24 hours | Delayed or unclear responses | “Who will be my point of contact?” |

How to Plan Quantity, Budget, and Lead Time

Your unit price depends on material, size, complexity, and order volume. For custom laundry bags wholesale, the curve is simple: higher MOQs usually bring lower per-unit pricing and better scheduling priority.

MOQ, Unit Price, and Lead Time

- MOQ: Often starts at 500–1,000 units per SKU for mesh bags; can be lower for existing molds or shared materials.

- Lead time: Typically 15–35 days after PPS approval, plus shipping. Peak seasons add a buffer.

- Price breaks: At 1,000 / 3,000 / 5,000+ units; embroidery and multi-color prints influence costs.

Comparison Table: Typical Wholesale Ranges

| Order size | Indicative lead time (after PPS) | Typical customization options included | Notes |

|---|---|---|---|

| 500–1,000 | 20–30 days | 1–2 logo colors, standard sizes | Good for pilots, new sites |

| 1,000–3,000 | 20–35 days | 2–3 logo colors, color-coded zippers, labels | Best balance of price & flexibility |

| 3,000–10,000 | 25–40 days | Full range of sizes, embroidery upgrades | Plan early for peak season |

| 10,000+ | 30–45 days | Custom yarn colors, special packaging | Reserve capacity; stagger shipments |

The Sample Path: From Tech Pack to Pre-Production Sample (PPS)

Sampling is where you remove surprises. Here’s the flow we recommend for custom laundry bags:

- Kickoff & tech pack. You share the spec: dimensions, fabric weight, mesh type, closure, logo, and placement.

- Prototype sample (optional). Quick fabric-only mockup to validate size and closure feel.

- Color Lab-Dip / Print Strike-Off. Confirm Pantone matches and logo clarity.

- Pre-Production Sample (PPS). Built on the production line with final materials and trims.

- PPS approval. You sign off; we lock settings.

- Bulk production. We scale with the approved SOP, then complete QC and packing.

Checklists for PPS review:

- Measure length/width/gusset; confirm tolerance.

- Inspect stitching density (e.g., 8–10 SPI) and bar-tacks at handles and drawstring points.

- Verify zipper auto-lock and puller strength.

- Wash test at your target temperature; check for color bleed and logo stability.

- Confirm packaging: polybag, set labels, carton size, and barcode if needed.

Printing, Embroidery, and Color Coding That Actually Last

Branding is more than a logo. Good visibility helps sorting and accountability.

- Screen print: Use plastisol or water-based inks rated for the wash temps you’ll run. Ask for cure temp confirmation.

- Heat transfer: Ideal for complex art; spec wash-resistant films and edges rounded to minimize lift.

- Embroidery: Choose thread that matches your cycle temps; request softer backing for delicates.

- Color coding: Use zipper tape, cord locks, or fabric panels to segment teams or floors. Print large department letters on the personalized laundry bag front to speed sorting.

Durability tip: Request a “50-cycle promise.” It’s simple: we provide test results or replace any early failures that fall under workmanship.

Comparison Table: Branding Methods for Custom Laundry Bags

| Method | Look & feel | Durability in wash | Best use cases | Cost impact | Notes |

|---|---|---|---|---|---|

| Screen print | Bold, flat colors | High (with proper cure) | Logos, size marks, QR | Low–Medium | Great for 1–3 colors |

| Heat transfer | Photo-quality | Medium–High | Complex logos, gradients | Medium | Round corners to prevent lift |

| Embroidery | Premium, textured | Very High | Logos on thicker mesh/panels | Medium–High | Test on mesh to avoid puckering |

| Woven label | Clean, minimal | Very High | IDs, sizes | Low | Heat-seal or stitch-in |

Closures, Seams, and Hardware: What Makes Bags Last

A bag fails at the weakest point, usually the closure or seam. For long-life custom laundry bags, specify:

- Closures: Auto-lock zippers for wash cycles; drawstrings with spring-loaded locks for cart transport; buckles for heavy loads.

- Seams: Double-needle or overlock plus top-stitch; bar-tack at stress points.

- Tapes & bindings: Soft bindings reduce abrasion on delicates.

- Hardware: Rust-proof metals or high-grade plastics; check for snag-free shapes.

Testing: Ask for seam strength data or perform a simple pull test on PPS (e.g., 15–25 kg depending on size and fabric).

Sustainability and Compliance (REACH and Beyond)

When you buy custom laundry bags wholesale, compliance isn’t optional. We source environment-friendly materials that can pass REACH and related tests. If you require specific certifications (e.g., recycled yarn or chemical limits), mention them at RFQ stage so we propose the correct fabric and inks from day one.

Documentation to request:

- Material composition and origin

- Dye/ink compliance declaration

- Washing instructions and limits

- Recycled content (if applicable)

- Test reports (colorfastness, pull strength)

For general textile safety context, see OEKO-TEX resources on chemical limits (external reference). For broader choices in the market, compare custom laundry bag options on major marketplaces like custom laundry bag options to benchmark features and pricing (competing link).

Packaging, Kitting, and Labeling to Speed Deployment

Good packaging reduces setup time at site launch. Consider:

- Singles vs. sets: Retail-style sets (e.g., 3-pack or 5-pack) with size variety for personalized laundry bag programs.

- Carton labels: Include SKU, color, size, and barcode for quick receiving.

- Insert cards: Include care icons and user instructions.

- Kitting: Pre-sort by location or employee ID to streamline hand-outs.

- Retail finishing: Hangtags or header cards for store shelves.

If you need inspiration, review our Laundry Bag Set and patterned Flower Print Mesh Laundry Bag Set.

Logistics: Incoterms, Freight, and Delivery Windows

For custom laundry bags wholesale, you’ll pick an Incoterm that suits your team:

- EXW/FOB: You arrange freight; good if you have a forwarder.

- CIF/CFR: Supplier handles sea freight to your port.

- DAP/DDP: Delivered to your door, with or without duties prepaid.

Lead time buffers:

- Sampling: 7–15 days

- Production: 15–35 days

- Shipping: 7–35 days (air vs. sea)

- Customs & last mile: 2–7 days

If you have phased rollouts, plan split shipments—air for the pilot, sea for the balance.

Quality Control: What to Check Before the Goods Ship

Even robust specs need verification. A final inspection should include:

- Dimensions & weight: Random sample across cartons.

- Seams & stitches: Count stitches per inch, check bar-tacks, look for skipped stitches.

- Closures: Test zipper lock under shake; drawstring lock under pull.

- Prints & embroidery: Rub and wash tests; confirm Pantone.

- Cartons & labeling: Verify counts, barcodes, and carton strength.

Ask for a photo report plus a few couriered golden samples from bulk to keep as your control set.

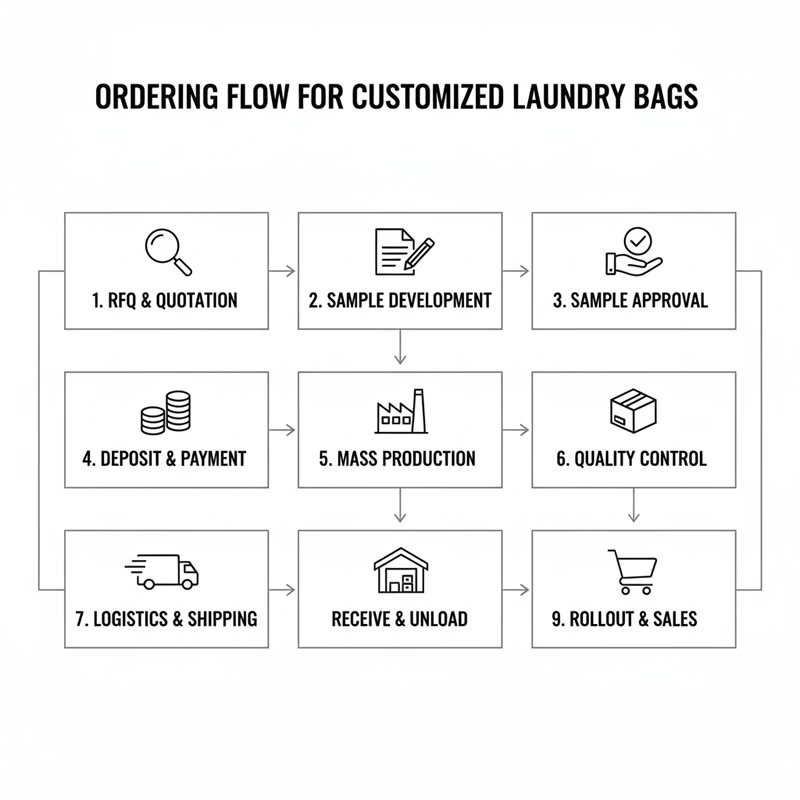

Step-by-Step Ordering Workflow for Custom Laundry Bags

Follow this sequence to align teams and move fast:

- Define goals & quantities. Include SKUs, color codes, and delivery windows.

- Choose materials & features. Decide mesh type, closure, branding, and packaging.

- Request a formal RFQ. Include target Incoterms and destination.

- Review quotation & timeline. Balance unit price, MOQ, and schedule.

- Approve PPS. Confirm wash tests, color, and fit.

- Confirm purchase order. Lock payment terms and production slot.

- Production & midline checks. Keep comms open; request progress photos.

- Final QC & ship. Receive inspection report and tracking.

- Rollout & feedback. Pilot with one site; collect notes for the next batch.

Real-World Specification Examples (Use These as Starting Points)

Uniform Program – Heavy Use

- Coarse polyester mesh, 150–180 gsm

- Size: 60 × 70 cm, gusset 8 cm

- Auto-lock zipper, #5 coil, reinforced ends

- Screen print department letter 12 cm tall, front center

- Barcode label 3 × 5 cm, inside hem

- Pack: single in polybag, 50 per carton

Hotel Linen – Mixed Loads

- Fine polyester mesh, 90–100 gsm

- Size: 50 × 60 cm, flat

- Drawstring with spring lock, bar-tacks at eyelets

- Heat transfer logo 8 × 8 cm, top right

- Color-coded cord locks by floor

- Pack: sets of 3 (S/M/L) with insert card

Retail Set – Patterned

- Fine mesh + printed panel

- Sizes: 20 × 30, 30 × 40, 40 × 50, 50 × 60, cylinder 18 × 18 × 25 cm

- Embroidered logo patch 4 × 4 cm

- Header card with hang-hole

- Pack: 5-piece set

- See reference: Flower print mesh set

Where Our Factory Adds Value for Your Project

As a manufacturer since 2014, we focus on repeatable quality:

- Mesh expertise: Fine and coarse mesh tuned for airflow and abrasion.

- Logo durability: Screen, heat transfer, and embroidery that stand up to real wash cycles.

- Compliance: Environment-friendly raw materials; REACH test capability.

- OEM & design support: From idea to artwork to PPS.

- Global supply: Serving Europe, North America, South America, Korea, and Japan.

- Scale: We support pilots and multi-site rollouts for custom laundry bags and related storage items.

Explore more options on our products.

Frequently Asked Questions

1) What’s the best mesh for daily hotel use?

Coarse polyester mesh (120–180 gsm) balances airflow and strength. It’s reliable for towels and linens, and ideal for custom laundry bags that see constant cycles.

2) Can you match our brand colors and keep them stable in wash?

Yes. We lab-dip to your Pantone and run wash tests at your target temperature. For large orders, we can color-match zippers, cords, and labels for a full personalized laundry bag look.

3) How do we reduce loss and mix-ups?

Print large department letters, add scannable codes, and color-code trims. Customized laundry bags with unique IDs per user cut sorting time and shrinkage.

4) What’s the typical lead time for wholesale?

After PPS approval, production is usually 15–35 days, plus shipping. Ask about split shipments if your rollout is phased.

5) Can we order small pilots before a large rollout?

Absolutely. Start with 500–1,000 units to validate size, mesh, and branding. Scale to custom laundry bags wholesale with the proven spec.

You’re ready to spec and order with confidence. We are the original manufacturer—since 2014—of mesh laundry bags, washing bags, and storage solutions. Let’s turn your brief into a production-ready sample and a smooth rollout.

Start your project: Share your quantities, sizes, and branding files. We’ll send a fast quote and set up your pre-production sample.

Explore custom laundry bag options on a major marketplace to benchmark features: custom laundry bag options.